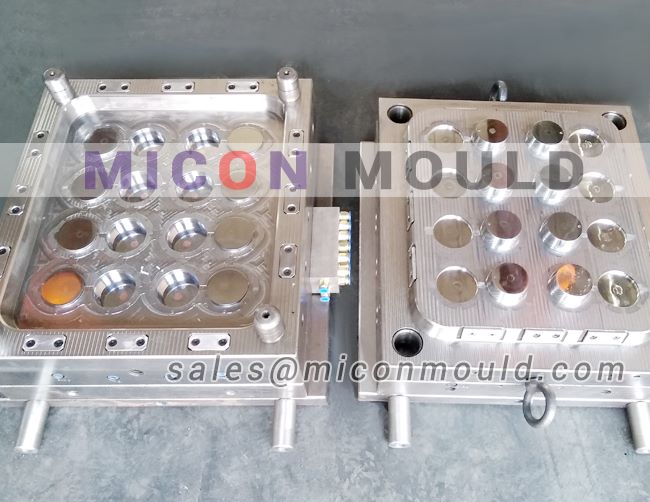

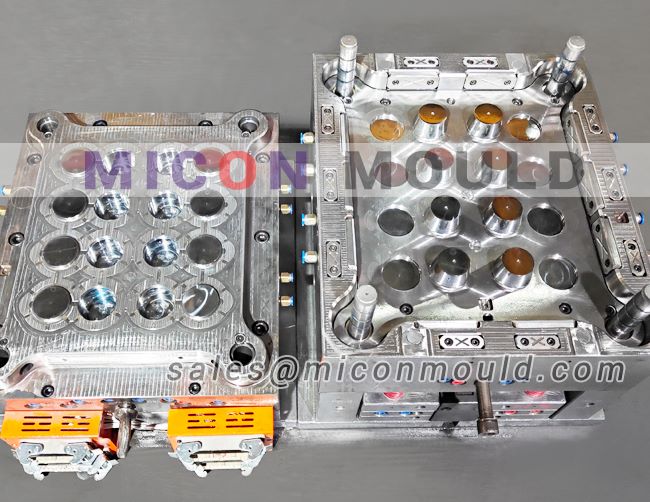

sauce cup mould

Sauce cup molds are plastic molds used to produce disposable sauce cups. They are typically made of steel and mass-produced through injection molding. The design of these molds must consider the cup shape, sealing performance, and capacity (commonly 25ml to 200ml).

As part of the production equipment, sauce cup molds are used in conjunction with plastic granules to produce sealed sauce containers that meet the needs of takeout, catering, and other similar scenarios.

Sauce containers come in two structures: integrated and separate.

Design and Size of the Sauce Cup

The design and size of the sauce cup you want to produce play a significant role in mold selection.

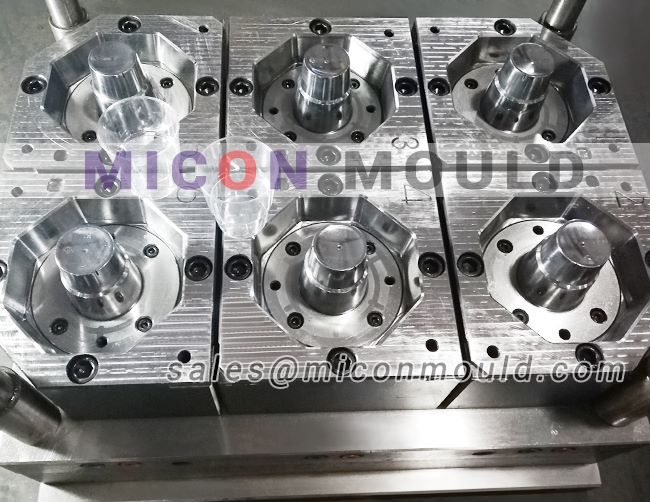

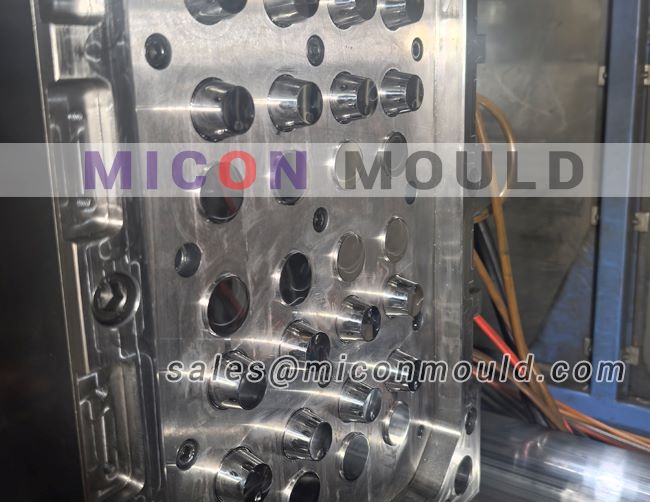

Shape and Features: Consider the shape of the sauce cup, whether it is round, square, rectangular, or has special features such as ribs, handles, or lids. The mold must be designed to accurately replicate these features. Complex shapes may require more advanced mold - making techniques and may increase the cost of the mold. For example, if you want to produce a sauce cup with a unique ribbed design for better grip, the mold needs to be precisely machined to create those ribs.

Size: The size of the sauce cup determines the size of the mold cavity. Larger sauce cups require larger molds, which may need more powerful injection molding machines. It is important to ensure that your existing or planned production equipment can accommodate the size of the mold. Also, consider the wall thickness of the sauce cup. Thicker walls may require longer cooling times and different injection molding parameters.

Quality and Precision of the Sauce Cup Mould

The quality and precision of the mold are essential for producing high - quality sauce cups.

Dimensional Accuracy: The mold should be manufactured with high dimensional accuracy to ensure that the produced sauce cups meet the required specifications. A precise mold will result in consistent product quality, with minimal variations in size and shape. Look for a mold supplier that uses advanced manufacturing techniques and quality control measures to ensure dimensional accuracy.

Parting Line and Ejection System: The parting line of the mold is where the two halves of the mold meet. A well - designed parting line should be as inconspicuous as possible on the final product. The ejection system of the mold is responsible for removing the finished sauce cup from the mold cavity. A reliable ejection system ensures that the sauce cup can be ejected smoothly without damage.

- 1. Excellent cooling system;

- 2. High-precision CNC machining process;

- 3. Select steel materials for each part of the mould;

- 4. Good exhaust system specially designed;