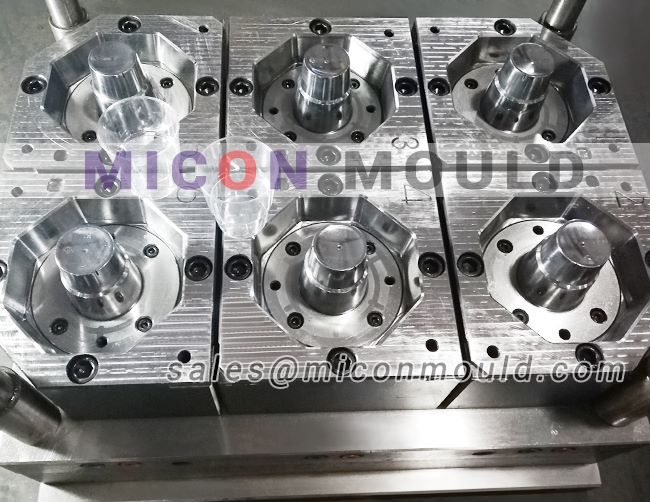

PS transparent cup mould

Thin wall injection cup moulds are commonly used in industries like food and beverage, packaging. These thin wall cup moulds are designed to create lightweight and cost-effective cups that are durable and of high quality.

1. Use high-quality materials. The key to making a successful thin wall injection cup mould is using high-quality steel materials. Choose correct materials that are durable and have good thermal conductivity to ensure a smooth and efficient moulding process.

2. Design with precision. Use advanced software for designing, ensure that the design is precise and has the correct dimensions to produce cups with thin walls.

3. Optimize the cooling system. Optimize the cooling system within the mould to ensure uniform cooling and prevent warpage or defects in the final product.

4. Precision mold processing. Precise CNC equipment, ensure that the wall thickness is uniform throughout.