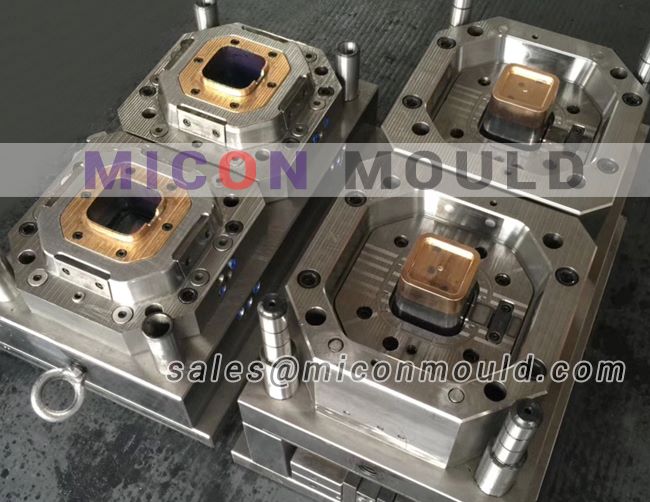

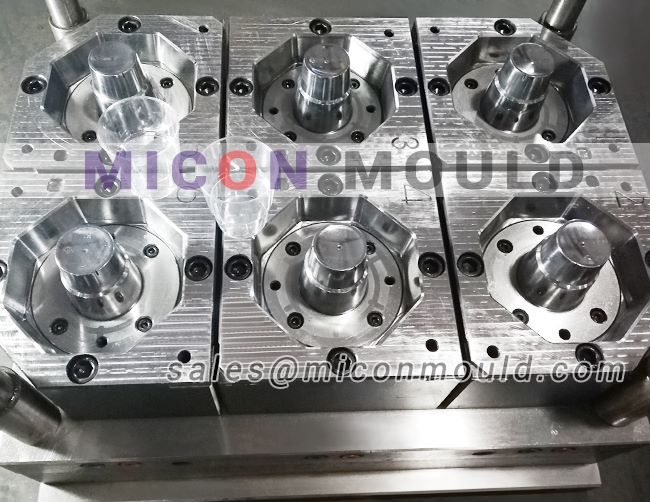

thin wall bucket mould

What's Advantages of Thin Wall Mould:

Lightweight and Cost-Effective: Thin wall mould offers significant weight reduction compared to traditional manufacturing methods. This not only contributes to resource conservation but also lowers transportation costs. Additionally, reduced material consumption leads to cost savings, making it an economically viable option for many industries.

Design Freedom and Complexity: With thin wall mould, intricate and complex designs can be easily achieved. The flexibility of molds allows for the production of geometrically challenging shapes, including undercuts, curves, and fine details. This opens up new possibilities for designers and engineers to create innovative and visually appealing products.

Enhanced Product Performance: Thin wall mould offers improved performance characteristics in certain applications. For example, in the automotive industry, lighter components produced through thin wall moulding can contribute to fuel efficiency gains. Similarly, in electronics, thinner casings allow for better heat dissipation, leading to improved performance and reliability.