medicine cup mould

What exactly is a medicine cup mould?

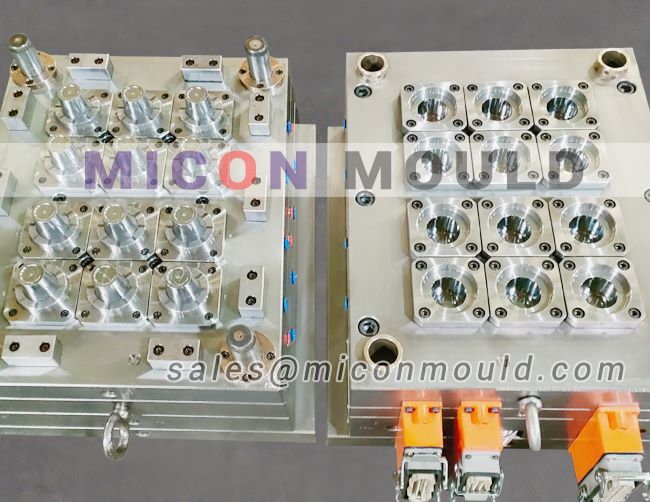

A medicine cup mould is a specialized tool used in the manufacturing process to create medicine cups. It's like a negative imprint of the final product. Think of it as a custom - made container where molten plastic or other materials are poured in. Once the material cools and solidifies, it takes the shape of the mould, resulting in a perfectly formed a cup with graduations.

These moulds are typically made from high - quality metals like steel. Steel moulds are known for their durability and long lifespan. They can withstand high temperatures and the pressure of the injection - molding process without getting damaged easily.

The Manufacturing Process

The process of using a medicine cup mould starts with designing. Engineers use advanced computer - aided design (CAD) software to create a 3D model of the medicine cup. This model takes into account all the details, such as the shape, size, markings, and any special features of the cup.

Once the design is finalized, the mould is fabricated. Specialized machining tools are used to cut and shape the metal according to the design specifications. This is a highly precise process, as even the slightest deviation can affect the quality of the final medicine cup.

After the mould is made, it's installed in an injection - molding machine. Plastic pellets are fed into the machine, where they are heated until they turn into a molten state. The molten plastic is then injected into the mould under high pressure. The pressure ensures that the plastic fills every nook and cranny of the mould, creating a detailed and accurate copy of the design.