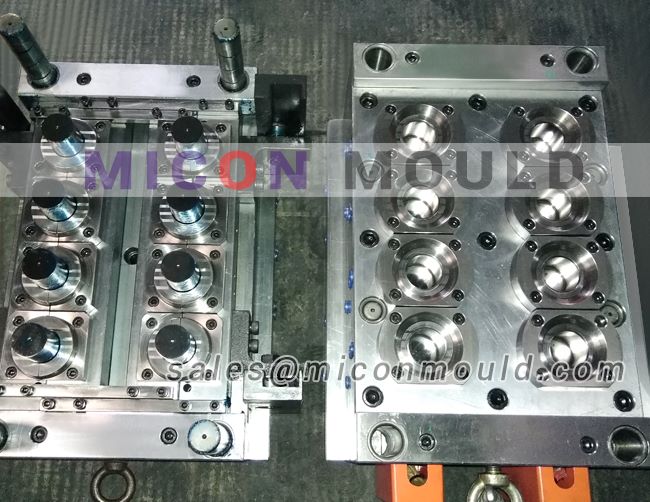

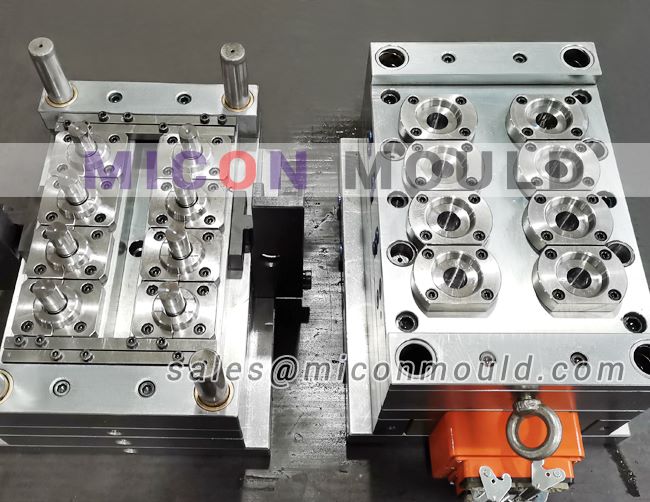

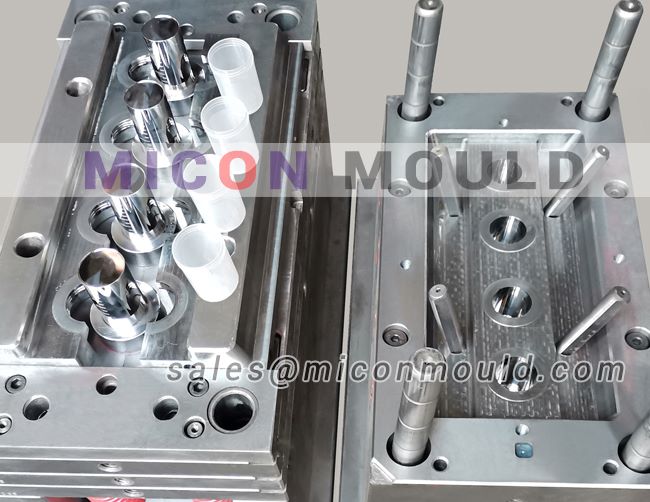

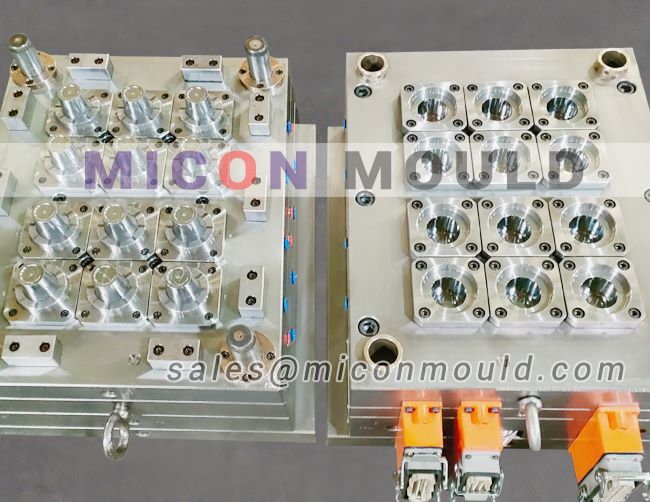

urine container mould

The urine cup mold is a key tool used for producing disposable medical urine cups, usually using injection molding technology. The mold design needs to meet requirements such as high precision, corrosion resistance, and easy demolding. Common specifications include 20ml, 30ml, 40ml, 50ml, 60ml, 80ml, 100ml, 120ml etc.

Core Features of Urine Cup Molds

Material Selection: The mold steel is typically pre-hardened acid-resistant steel (such as 2316, M340). These materials offer strong corrosion resistance, excellent polishing performance, and a mirror finish. After quenching, their hardness reaches over 52 HRC, exhibiting high wear resistance, making them suitable for the high-precision requirements.

Structural Design:

Cooling System: Optimized flow channel design ensures rapid temperature balance in the mold, shortening the molding cycle (typically 12-15 seconds/cycle) and improving production efficiency.

Demolding Mechanism: Stripper plate.

Precision and Lifespan: Mold lifespan must reach over 1 million cycles, with dimensional tolerances controlled within ±0.02mm to ensure urine cup sealing, accurate markings, and smooth rim.