safety goggles mould

what is Safety Goggles Mould?

Material: Polyvinyl chloride resin is melted and injected into molds.

Process: Molten plastic is forced into the mold under high pressure, rapidly cooling and hardening to form the frames.

Mold Types: Common methods include injection molding for complex shapes and large volumes.

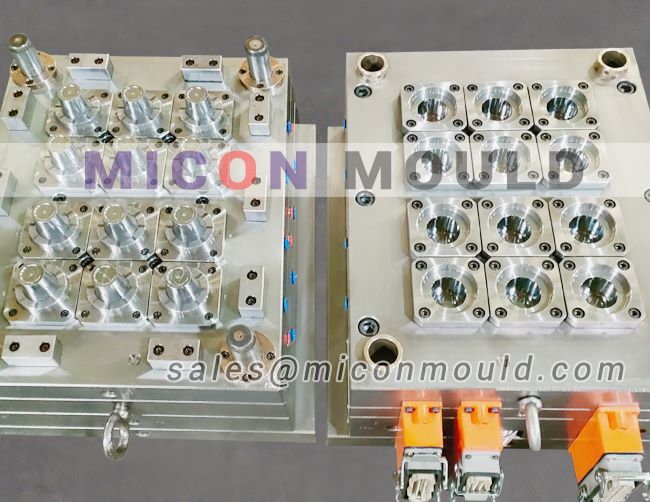

Mold Materials: Molds themselves are made from hardened steel to withstand heat and pressure, ensuring accuracy and longevity.

Key Features of Goggle Moulds

Precision Engineering: Essential for creating dimensionally accurate, high-quality lenses and frames, minimizing waste.

Durability: Moulds are designed to resist high temperatures and wear for long-term, efficient production.

Adaptability: Can be designed for various functions, including medical or general industrial use, using different plastics and features like anti-fog surfaces.