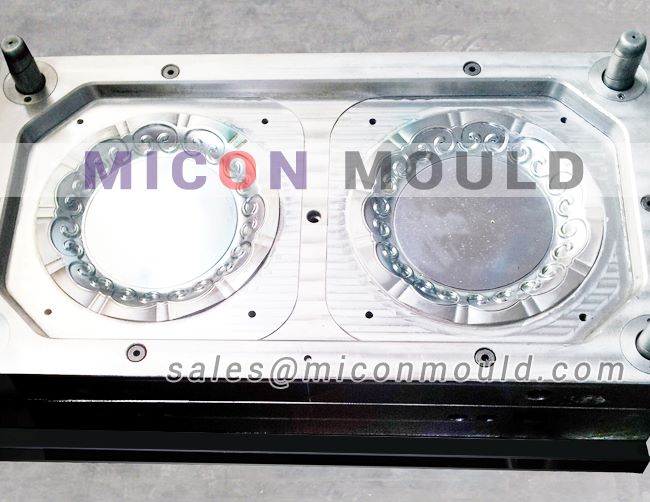

food serving plate mould

One of the main advantages of a plastic food tray mold is its ability to produce large quantities of food trays in a short time. The mold is designed to handle high volumes of plastic, allowing for faster production times and increased efficiency. This makes it an ideal option for businesses that need to manufacture large quantities of food trays quickly.

In addition to being efficient, the products are also very durable. They are made from high-quality materials that are designed to withstand the wear and tear of regular use. This means that food tray molds that are properly maintained can be used for years without needing to be replaced.Another benefit of plastic food tray molds is their flexibility. They can be used to create a wide range of food tray designs, from simple to complex. This allows for a high degree of customization, which is important for businesses that want to differentiate themselves from their competitors.The molds are a valuable tool for businesses in the food industry. They are efficient, durable, and flexible, making them an ideal choice for businesses that need to produce high-quality food trays in large quantities. With proper maintenance, a plastic food tray mold can provide years of reliable service, helping businesses to compete in a highly competitive market.