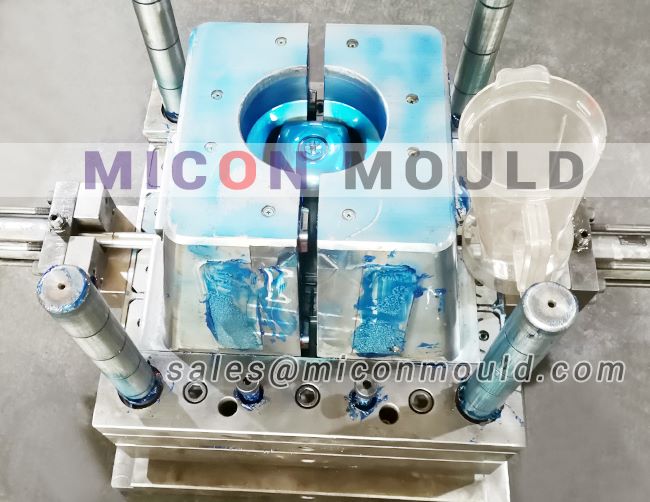

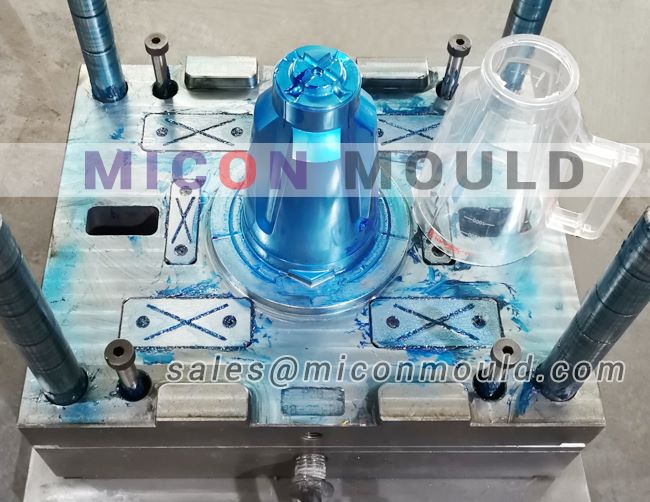

fresh juice blender mould

Juicers, which are popular for blending fruit juices, smoothies, and various beverages, are becoming increasingly common and come in a wider variety of types. How to manufacture so many juicers with different appearances? Of course, it uses various plastic moulds. Most of the parts of a juicer are manufactured using injection molding. If you need a high-quality juicer, we can provide solutions.

The various parts of a juicer need to fit together well, so the dimensions, shrinkage rate, and structure of the parts need to be considered when manufacturing the mould.

The materials used for each component are also important, as this is the foundation for the juicer's durability. The body is usually made of transparent plastic, but our molds have used PS, PC or other plastics.