Thin wall container is very popular in market all over the world. typically, container with a wall thickness less than 0.6 mm is considered as “thin wall”. Thin wall container features: thin wall, light weight, high yield, short turnaround period, so the mould requirements are very high.

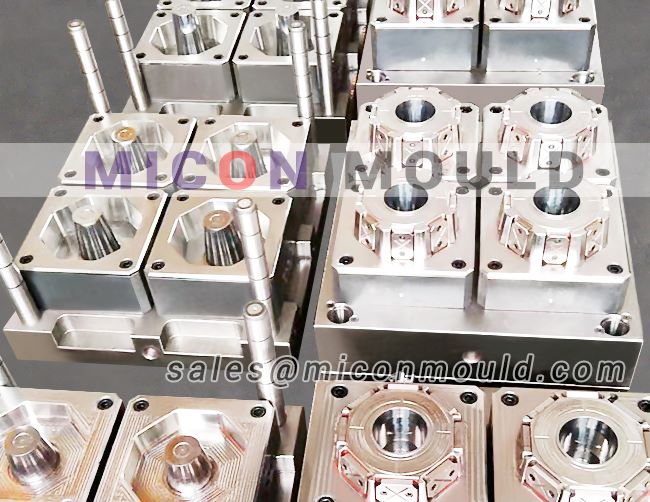

Thin wall injection molding needs molding speeds 4-6S, so it requires a very good cooling system and high hardness in order to ensure the short cycle and the mold life. For such molding speeds, we should add water channel as more as possible,strengthen the water circulation. Usually we use chilled water. So our mould steels are stainless steel.

Besides, we always adapt with BeCu to help the mould cooling, because BeCu has good thermal conductivity.

In China, Micon Mould has rich experience in thin wall mold making.

As for the thin wall mould, we always use high speed milling machine and some other high precision tooling machine to tool it, the dimension tolerance should be controlled within 0.05mm. And there will have many inserts so as to maintain the molds.

Regarding the ejection system for thin wall container mould, we usually use air to blow off the cavity. It requires the parts demolding quickly and then use air ejection or air with stripper plate assistance.

Thin wall container design main points:

1. The leakage shall be zero.

2. The container body and cover shall fit properly, leave gap 0.15-0.2mm.

3. There shall leave 0.8-1mm room when design the joint of cover edge and container.

4. The rib design shall be thinner than product, thin wall products are mostly transparent material, too thick rib will bring bubbles.

Want to make a full range of thin wall container to meet market demand? Then contact us quickly, We offer high quality thin wall mould as well as thin wall mold solutions.

Micon Mould is Professional Manufacturer of Thin Wall Mould

With the rapid development and popularization of takeout industry, there is an increasing demand for disposable packaging products. How to reduce costs is the key. Micon Mould helps you solve this problem. Multi cavity, thin wall and high speed, we will meet your needs.

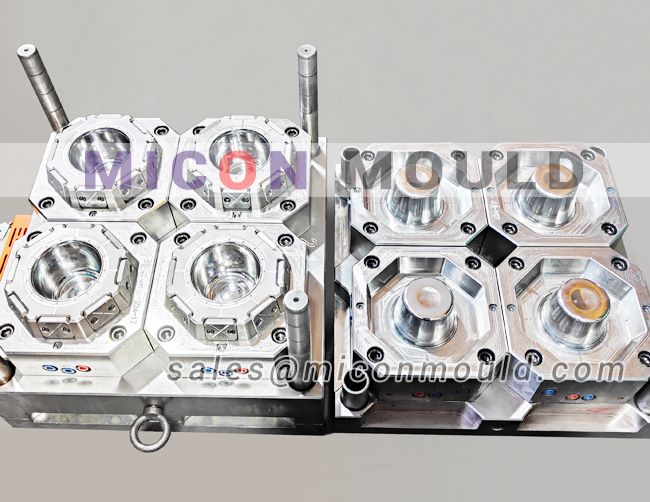

Micon Mould is a professional manufacturer of thin wall mould. The thin wall mold we manufacture are round, square, and oval. The number of cavities ranges from 1 to 8 cavities, and the minimum wall thickness can reach 0.4mm, to ensure uniform wall thickness while ensuring the hardness of the thin wall container.

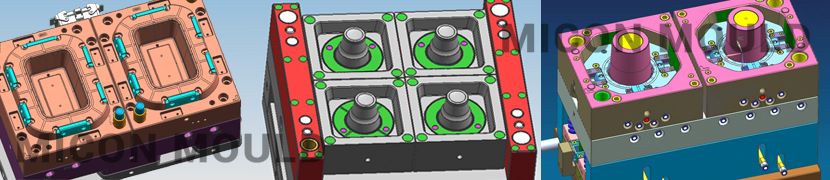

Thin Wall Mould design:

Good mould design is the prerequisite for the manufacture of thin wall container mold. Our company has a senior mold design team to analyze the mold structure and product structure in all aspects, including demolding angle, product surface miniature, pouring system, exhaust system, cooling system, etc. The most important and most prone problems of these molds will be repeated trials during mold structure design.

Thin Wall Mould Cooling system design:

The design of the cooling system is a relatively complicated task, that is the cooling effect and uniformity of the cooling must be considered, and the influence of the cooling system on the overall structure of the mold must be considered. The specific location and size of the cooling system are determined; key parts such as the movable mold or cooling of inserts; cooling of side sliders and side cores; design of cooling elements and selection of cooling standard elements. By inserting BeCu into the mold to achieve rapid cooling, reduce the cooling time during injection molding, increase product production efficiency, and greatly reduce production costs.

Exhaust system design:

Thin wall container have higher requirements for exhaust. In addition to avoiding surface burns and insufficient injection volume, excellent exhaust can also eliminate product defects and reduce mold pollution. We have rationally designed the venting method and size of the venting slot, which reduces the injection pressure and injection time, makes the molding of plastic parts easy, and reduces the energy consumption of the machine.

Thin Wall Mould steel selection:

S136 or H13 is generally recommended for fast thin wall mold. After quenching, the hardness of the core and cavity can reach HRC45-52, and the life of the mold can be improved, which is suitable for long-term efficient and stable operation.

How can we improve the accuracy of thin wall injection molding parts?

1. Close the molding pressure: in principle, it should be greater than the total pressure of the plastic injection into the mold, with no burrs as the benchmark.

2. The pressure and speed have the same relationship. The purpose of the action in the mold is to make the raw material enter the mold uniformly, thoroughly, and fill every corner with an appropriate amount. If it is too low, it will cause short shot and shrinkage. If it is too high, there will be burrs, oversaturation, mold sticking, burning, vulnerable molds and high internal stress.

3. The speed of the speed is to determine the condition of the raw materials in the mold runner and the finished product. There are burrs, oversaturation, scorching, and short shots, shrinkage, poor bonding and easy breakage.

4. The temperature of the raw materials is different, and the temperature is different. If the melt is too low, the color will not be uniform, and the internal stress of the finished product will increase. If the temperature is too low and the pressurization is too high, it may cause the screw to break. If the temperature is too high, the product has burrs, and the temperature difference due to cooling will cause shrinkage. The raw material will decompose, turn yellow, discolor and break easily. The cooling time becomes longer, and the air is not easy to discharge.

Advantages of the Thin Wall Container Mold

1. Increased production efficiency: Thin wall container molds have a faster cycle time, which means more containers can be produced in a shorter period of time. This results in increased production efficiency and cost savings.

2. Improved product performance: Thin wall containers are lighter and more durable than traditional containers, making them ideal for use in packaging applications. They are also less likely to crack or break, making them safer for consumers to use.

3. Cost savings: Thin wall container molds are often less expensive to produce than traditional molds, and they require less material to manufacture each container. This leads to cost savings on raw materials and reduced production costs.

4. Versatility: Thin wall containers can be manufactured in a variety of shapes and sizes, making them suitable for a wide range of packaging applications. They can also be produced in different colors, making it easier to identify the contents of each container.

5. Enhanced product appearance: Thin wall containers have a sleek and modern appearance and suitable for in-mold labeling, that can enhance the overall look of a product and increase its market appeal.

Technical points of thin wall container mold:

1. Specially designed zero-degree lock system for thin wall injection mold;

2. Cooling system specially designed for thin wall molds;

3. High-precision machining process;

4. Select steel materials for each part of the mold;

5. Exhaust system specially designed for thin wall molds;

6. High-speed injection system;

Micon Mould is specialized in manufacturing high-quality thin wall container molds. After years of research, we have developed thin wall molds with different capacities, models and specifications, including rectangular, round, oval, and square; capacities from 200ml, 500ml to 3L varies. Our molds adopt a self-locking structure with multiple cavities, which not only improve production efficiency, but also facilitate daily maintenance. So far, nearly hundreds of sets of thin wall food container molds have been delivered to customers in different countries.