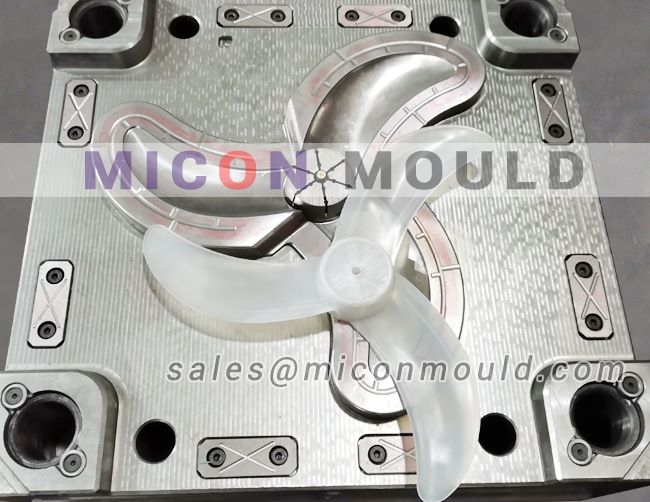

fan blade mould

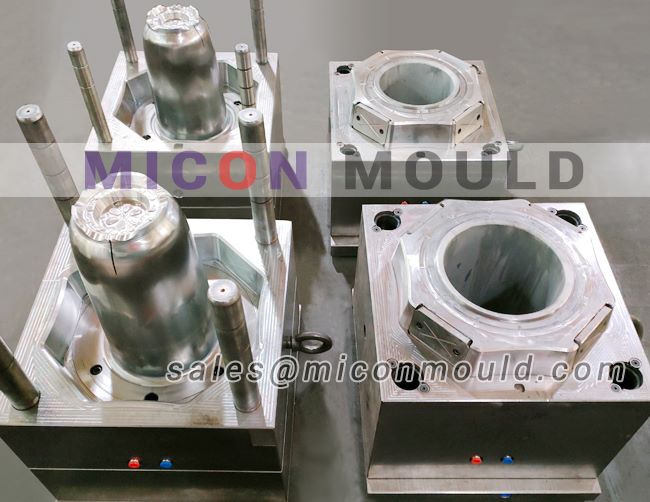

Fan mould sets, the key point is the fan blade mould, we need the very even injection points to keep the blade moulds' plastic filling are the same pressure and same distances. In the same time, we have to know that the moulding area's different temperature will caused the filling not even. this will cause the fan blade parts'gravity point will not in the center, so when the blade turning, there are ugly noise. We know how to make injection even and cooling effects on the moulding areas are the same.

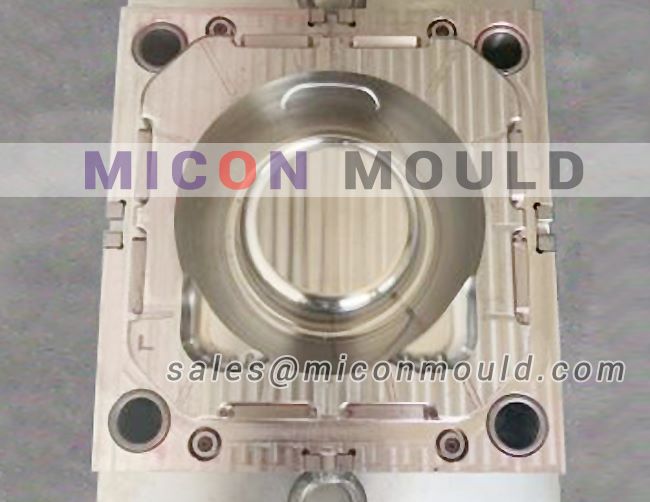

Design & Key Points for Plastic Fan Mold

The shape of the plastic fan blades is relatively simple. The first requirement is the principle of coincidence of the center of gravity. The size and thickness of all fan mould should be the same to ensure that the center of gravity of the product is located in the center of the plastic fan part. The second requirement is dynamic balance, that is, balance while rotating. These two requirements put forward higher requirements for the mold on fan blades, that is, on the premise of ensuring the reasonable design of the blade mould, improving the mold manufacturing process, and improving the mold manufacturing quality.

In addition to paying attention to balance in the plastic fan mold design process, the balance problem in mold processing is also important. The manufacture of mold cavity & core needs to be directly processed by a high-speed machine, and high-quality processing cutting tools are required. We should make sure each blade has the exact same shape and dimensional tolerances. After all machined, it should be inspected by 3-coordinate, and after all of the dimensions meet the tolerance, then fit the mold on fan blades and assembly it.