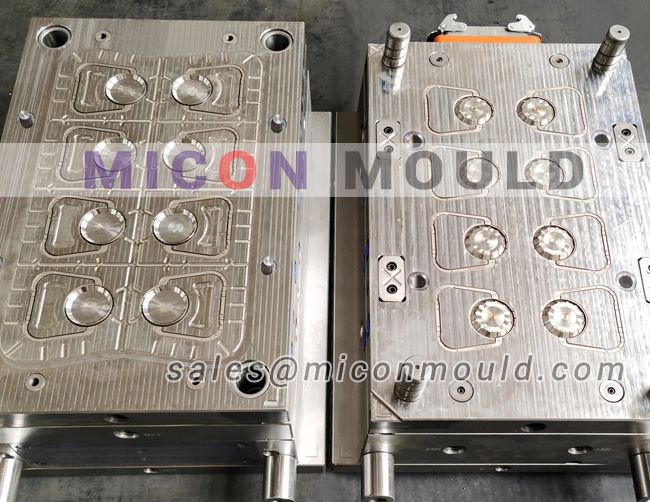

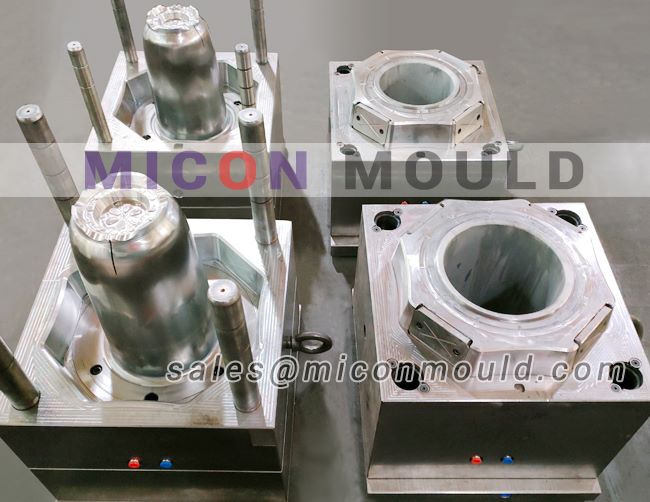

plastic handle mould

Manufacturing Process of Handle Moulds

Design Phase

The first step is the design phase. Using computer - aided design (CAD) software, engineers create a 3D model of the handle and the mould. This model takes into account all the design specifications, such as the handle's dimensions, draft angles, and parting lines. Draft angles are important to ensure that the handle can be easily ejected from the mould after it has solidified. Parting lines define where the two halves of the mould will separate.

Material Selection

Once the design is finalized, the appropriate material for the mould is selected. For plastic handle moulds, tool steel is a common choice due to its hardness, wear resistance, and ability to hold a fine surface finish. For metal handle moulds, different grades of steel or other alloys are selected based on the specific metal - forming process and the required properties of the mould.

Machining

The selected material is then machined using various techniques, such as milling, turning, and electrical discharge machining (EDM). Milling is used to remove large amounts of material and create the basic shape of the mould. Turning is used for cylindrical parts of the mould. EDM is a precise machining process that uses electrical discharges to remove material and is often used to create complex shapes and fine details in the mould.

Heat Treatment

After machining, the mould undergoes heat treatment to improve its hardness, strength, and wear resistance. Heat treatment processes, such as quenching and tempering, are carefully controlled to ensure that the mould has the desired properties.

Surface Treatment

The final step is surface treatment. This can include processes like polishing, plating, or coating to improve the surface finish of the mould and prevent corrosion. A smooth surface finish is important to ensure that the handles produced have a high - quality appearance and can be easily removed from the mould.