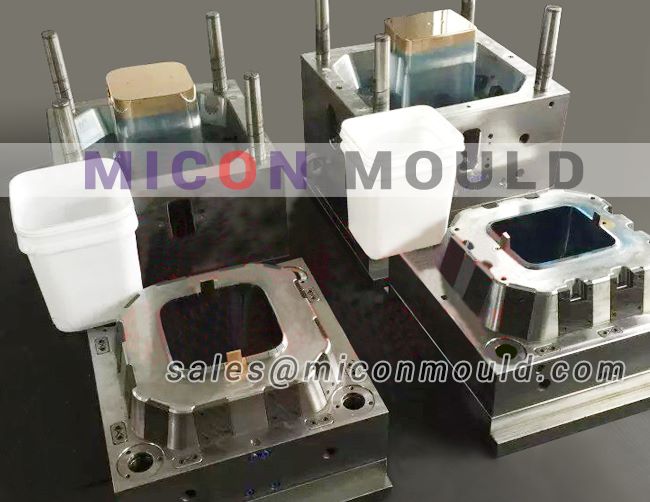

rectangular bucket mould

Features of the Bucket Mould

A bucket mold is a tool used in the plastic injection molding process to form plastic into the shape of a bucket. Here are some features of a typical bucket mould:

1. Cavity: The cavity is the interior space of the mold where the melted plastic is injected and forms the desired shape. Bucket molds typically have one or more cavities, allowing for the production of multiple buckets in one cycle.

2. Runner System: The runner system is the channel through which the melted plastic flows from the injection machine into the cavity. The runner system is usually designed to have a balanced flow of melted plastic to ensure an even filling of the cavity and reduce the risk of defects.

3. Ejection System: The ejection system is responsible for removing the finished bucket from the mold. This is usually done with the help of ejector pins and a stripper plate.

4. Cooling System: The cooling system is crucial in the molding process as it helps to solidify the melted plastic and retain the desired shape of the bucket. A well-designed cooling system ensures that the mold cools evenly and at a controlled rate.

5. Material: Bucket molds are typically made from hardened steel or aluminum and must be able to withstand the high temperatures and pressures involved in the molding process.

6. Precision: Precision is an important factor in bucket mold design as it affects the dimensional accuracy and surface finish of the finished bucket. High-precision molds use advanced manufacturing techniques to ensure consistent and accurate results.

7. Customizability: Bucket molds can be customized to meet specific requirements such as the size, shape, and design of the bucket. This allows for the production of a wide range of bucket designs for different applications.