Micon Mould is plastic toy mould maker, offers high quality toy mould to toy industry.

Micon Mould have high precision CNC equipment, dedicated to produce toy mould. At the same time of perfect process, we will make the size detection for each processed parts. And match with 3D design drawings to ensure the mould accuracy.

In additional, we attach importance to each step of toy mould processing, we will show clients each part in the form of photos and videos, form the raw material controlling, mould processing to mould test and shipment.

With the development of toy industry, we have rich experienced in plastic toy mould in the past several years. Can offer the best service, from plastic toy design, structure design, mould processing, plastic parts injection molding and so on.

The plastic toy mould has high requirements in design and convenience of plastic materials. The parts directly contacted by hands have high requirements for product segments. Due to the plastic toy mould structure limitation, the cooling difficulty is high, and the moulding cycle is required to be short.

Plastic toys have high safety requirements, especially the products must not have sharp edges to harm children. In some plastic toys that need to be assembled, the dimensional accuracy requirements are also very high, too loose or too tight will also bring a certain degree of danger. Higher plastic toy quality and better toy assembly depend on a high-quality plastic toy mould.

Let's get started on your new project!

Why use injection molding for toys?

1. High speed production: Injection molding is a fast and efficient process that enables manufacturers to produce a large number of identical toys in a short period of time.

2. Cost-effective: Injection molding is a cost-effective process as it requires less labor than other production methods. This results in reduced production costs, which is particularly important when producing toys that need to be sold at a competitive price point.

3. Enhanced design flexibility: Injection molding technology allows manufacturers to design toys to meet a wide range of specifications. This flexibility makes it easy to create toys of various shapes, sizes, and features with different textures, colors, and finishes.

4. Increased durability: Toys made using injection molding technology are often more durable than other types of toys. This is because the process enables manufacturers to use high-quality materials, and because the production method ensures that the toys are free of defects that can compromise their durability.

5. High quality finish: Injection molding technology allows manufacturers to create toys with a high quality finish that is consistent throughout the production process. This is because the process ensures that each toy receives equal amounts of materials and that the injection molding machine applies the right amount of pressure to produce high-quality finishes.

6. Environmentally friendly: Injection molding is an environmentally friendly method of production as the process produces minimal waste, and manufacturers can recycle or reuse excess materials to keep their production process sustainable.

7. Safe and non-toxic: Toys made using injection molding technology are safe and non-toxic, which makes them suitable for use by children of all ages.

Overall, the advantages of injection molding toys make it an ideal choice for manufacturers looking to produce high-quality, durable, and cost-effective toys that meet the needs of today’s consumers.

How to Make Plastic Toys Using Injection Molding?

So, let’s have an overview of how to make plastic toys using the injection molding method;

Step 1: Design the Toy

Conceptualization: Start with an idea, and draw the idea and structure of the toy. One should examine the age of the consumer target, security measures, and capabilities and utility.

3D Modeling: Draw the geometry using CAD to develop the 3D model of the toy model types. Then further use this mold design and the overall appearance of the final product.

Step 2: Create the Mold

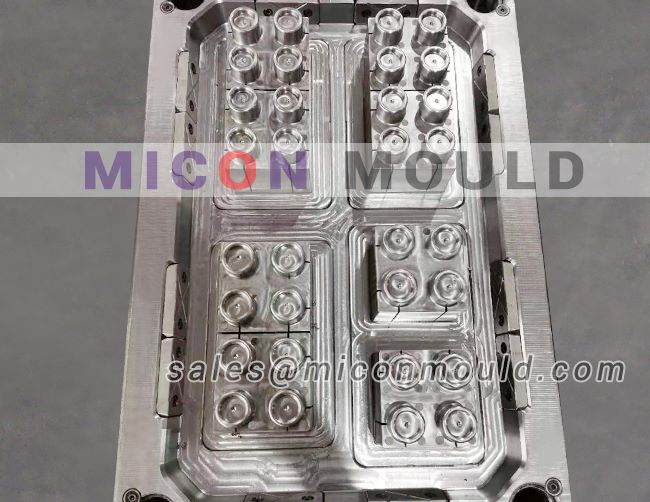

Mould Design: Afterwards, use the 3D model created and design the injection mold. This consists of the cavity that contains the molten plastic and the core for the inner shape of the product.

Material Selection: Selecting the proper material for the mold out of steel or aluminum, depends on the degree of production and its difficulty.

Mould Fabrication: Subsequently, create the mold using CNC machining or any other processes to enhance intensity. The mold can also be more polished to acquire a smooth surface.

Step 3: Injection Molding Toys Production