Plastic hanger injection molding:

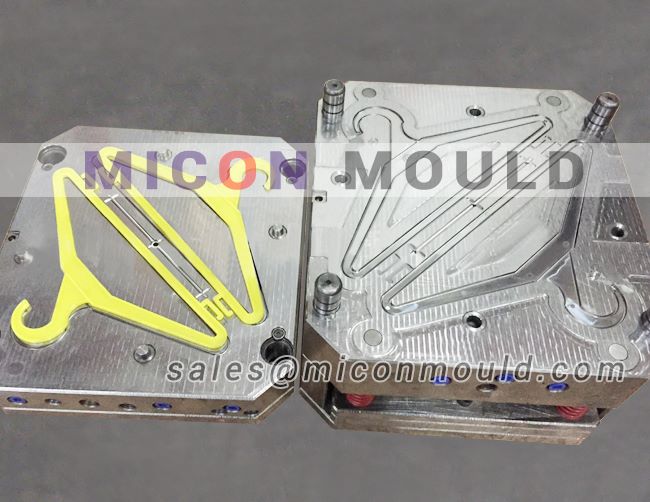

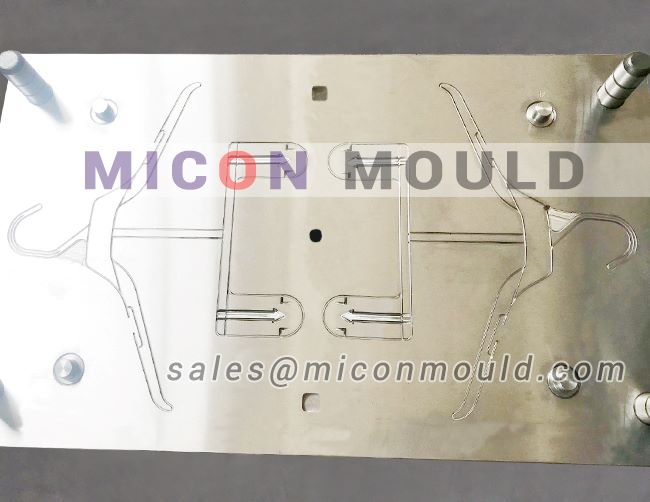

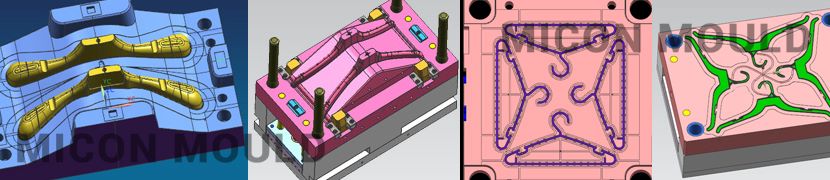

The method of manufacturing plastic hangers is injection molding technology. Molten plastic is injected at high pressure into a hanger mold, which is the inverse of the desired shape.

The raw materials for making plastic hangers are PP(polypropylene), PC(polystyrene), (ABS)acrylonitrile-butadiene-styrene copolymer, PC(polycarbonate), PVC(polyvinyl chloride) etc.

After preparation before molding, feeding, plasticzing, filling, pressure keeping, reverse flow, cooling and demoulding, the molding of a plastic hanger is completed. Hangers made of different raw materials have different performances. With the development of society, the forms of plastic hangers are becoming more and more diverse, such as plastic non-slip plastic hangers, travel portable hangers, folding hangers, etc.

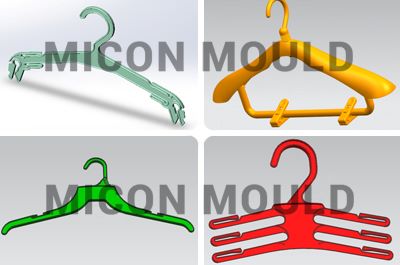

The types of plastic hangers:

The shapes of plastic hangers are mainly divided into two types. One is with a flat and long frame, and a relatively narrow cross-section of the shoulder. The slope of the frame is small, and the shape is light and thin. It is more suitable for drying light clothes.

The other is with a wider and shorter body. The two shoulder racks have a larger slope and a thicker width, and the shape is thick and solid, which is more suitable for hanging heavy clothes

What is the advantage of plastic hangers?

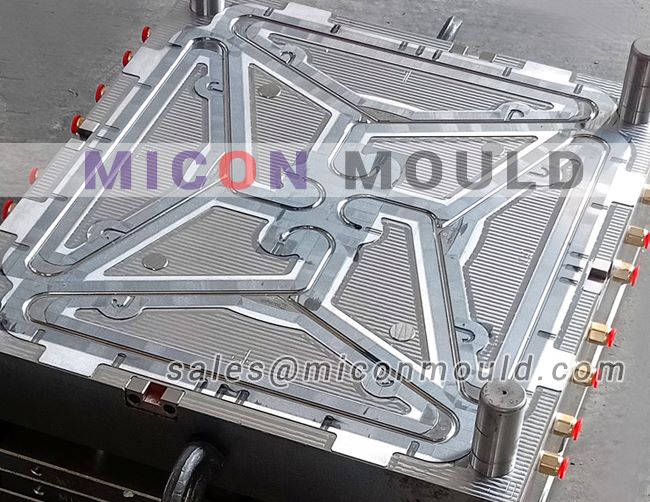

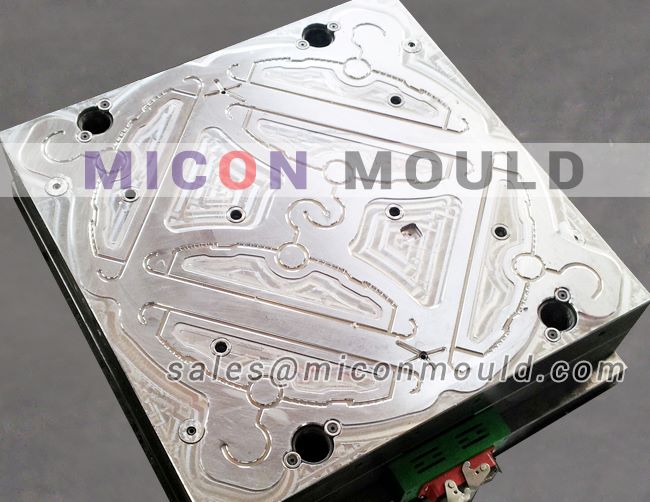

The advantages of plastic hanger are low cost, simple processing, light to carry and colorful colors. Standard hangers are normally ½ “thick and work well for most clothes. For heavier type clothing like coats, jackets, robes use a 1” thick hanger. Most plastic clothes hanger raw material is PP, PS, ABS. Customers can choose 2, 4, 8 cavities or more according to the output capacity and injection machine parameter.

When you need plastic hanger mould, please feel free to connect with me, we can offer you the high quality mould with reasonable price.

Material Classification Of Plastic Hangers:

PP(Polypropylene) is one of the most commonly used raw materials for hangers. It is non-toxic, odorless, low density, has good insulation and is not affected by humidity. Generally used for plastic suit hangers, shirt hangers, suit hangers, circulation hangers and other pendants.

PS(Polystyrene) is easy to process and form, good stability and not easy to deform, suitable for plastic foam suit hangers, jacket hangers, coat hangers, underwear hangers, trouser hangers, trouser hanger parts, etc.

ABS(Propylene-butadiene-styrene copolymer) is high temperature resistant, impact resistant and easy to process. Suitable for taller plastic suit hangers, trouser hangers-shirt hangers, underwear hangers etc.

PC(Plastic carbonate) is a colorless, odorless, non-toxic amorphous plastic with strong toughness and good dimensional stability. Commonly used in functional parts of plastic clothes hangers, such as: plastic hooks, springs, buckles, clips and some thin sheet hangers.

PVC has good heat resistance, toughness, ductility and high chemical stability. Applicable to plastic clothing accessories, such as: gaskets, beading.

How To Select Mould Steel For Hanger Mould?

When the melt plastic material is deformed in the hanger mold cavity, it flows and slides along the surface of the cavity, causing violent friction between the surface of the cavity and plastic, which causes the mold to fail due to wear. Therefore, the wear resistance of the material is one of the basic and important properties of the mold.

Hardness is the main factor affecting wear resistance. In general, the higher the hardness of the mold parts, the smaller the amount of wear and the better the wear resistance. In addition, wear resistance is also related to the type, quantity, shape, size and distribution of carbides in the material.

Generally we will consider P20 when choosing mold steel, this mold steel can guarantee at least 300,000 mold life under correct operation. Our minimum standard is P20 material, and poor steel is not guaranteed for quality. Of course, if want better steel can consider using 718H steel, the material itself can guarantee 500,000 shots, suitable for products with more output. We can use S136 steel if plastic material is corrosive which can guarantee the minimum level of 1 million shots. H13 steel material also has a certain degree of corrosion resistance and is with excellent work performance.

Maintenance Of Plastic Hanger Mould Before Production:

1. Clean the hanger mould surface for the oil, rust, and check mould cooling hole.

2. Check the sprue if there is residual material.

3. Check the fixed mold plate and confirm if the screw clamp is tightened.

4. After hanger mould fixed on the injection molding machine, injection operation should be carried out first.

Observe the movement of each part of the operation: whether there is abnormal phenomenon, the moveable parts such as the guide pins, the ejection pins, sliders whether there is wear, lubrication is good or not etc.