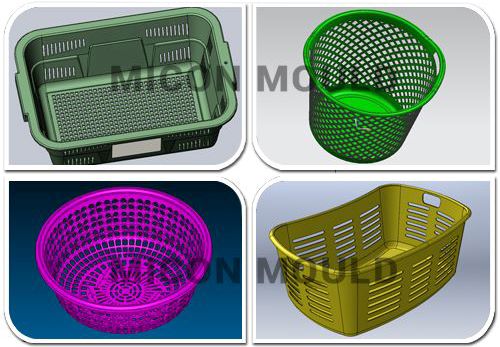

Plastic baskets are widely used in our daily life, including laundry basket, shopping basket, cosmetics storage basket, drain basket, picnic basket, fruit basket, vegetable basket, distribution basket, storage basket, rattan basket, folding basket, hand-held basket etc. As one of the leading plastic mould manufacturers in China, we have accumulated rich experience in designing and manufacturing Plastic Basket Moulds.

For plastic basket mould, Micon Mould has a team of rich experienced tooling engineers, mould design experts and well communicated sales specialist.

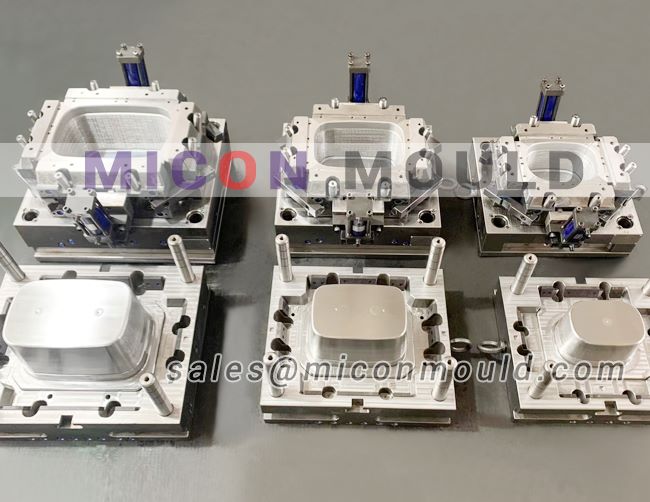

The plastic basket mould has many bumping holes. When designing the basket mould, the reasonable parting surface and R angle should be considered to avoid the phenomenon of bumping through holes and running edges. At the same time, the reasonable cooling channel is designed on both sides of the core and cavity to avoid the issue of melting line.

In terms of material selection of plastic basket mould, we generally recommend the most suitable one. Our plastic basket mould can have a long mould life under rapid and high-pressure injection.

Core and cavity steel: P20 (1.2311), 718H, H13 (1.2344) etc.

Steel of Mold Base: S45C, P20

Hardness of Cavity & Core:Pre-Hardness Steel : HRC 30~32+-1;Heat Treatment Steel : HRC 50~52+-1

Core pulling or Ejection system:Motor, oil cylinder, stripping plate, angel pin

Cooling System:In Core : Baffle or by pass cooling;In Cavity plate: Chain drilling type cooling

Surface Finish: Texture, EDM machining, polishing

Mold Life:

1. Pre-harden steel, min. 20~300000 shots

2. Harden / heat treatment steel: 60~800000 shots.

3. Stainless steel: 1 million shots.

Runner: 1. Cold runner; 2. Hot runner;

Delivery time: 50-55 days to T1 after mould drawing confirmed.

Packing: Standard Wooden Case

Production: We can also provide Pilot Run production and molding production

Over 10+ Experience as Plastic Basket Injection Mould Manufacturer

Main Points For Plastic Basket Mould:

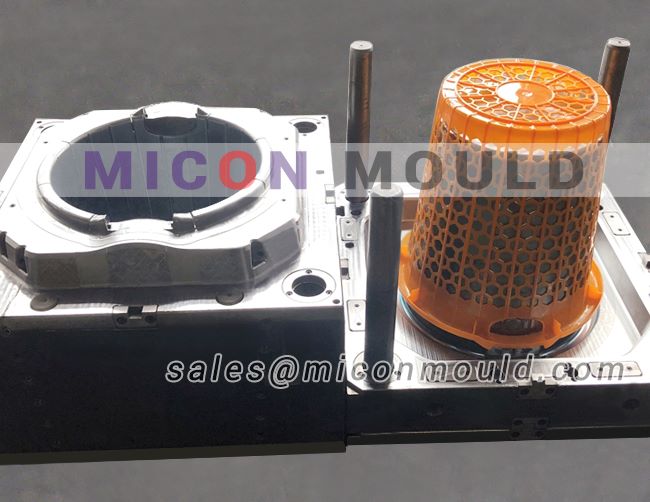

The basket should be designed according to the function of use and the thickness should be reasonable. It should not only make the product lightweight, but also ensure the strength of use, and the load should not be bent or deformed. The pattern should be designed with reasonable drafting slope and anti-deformation treatment according to the product design.

The basket adopts a multi-point needle valve gate, and the multi-point gate should achieve a balanced filling without trapping air. Combined with CAE analysis, gate location is determined. The choice of brand hot runner can make production stable and efficient.

Most of the plastic baskets are fixed mold four-slide core pulling, which can control the size of the mold and reduce the development cost compared with the moving mold slider core pulling. The action of the four sliders should be uniform, efficient and stable.

The cooling of the basket mold is very important. Reasonable cooling can reduce the deformation of the product and shorten the injection molding cycle. The appropriate size of water channel diameter and uniform distance can ensure uniform cooling of the mold.

Micon provides high standards of service and high-quality customized molds and components to meet on-time delivery and competitive prices. We can help you choose the right material for your upcoming project, as well as provide you with tooling solutions that are best for your ongoing production needs.

We are aiming to help start-ups or mature enterprises bring creative or innovative concepts or ideas into reality. Sincerely hope to establish business relations with more friends from home and abroad in the near future.

The Advantages of Using plastic basket moulds

One of the primary advantages of using plastic basket moulds is the cost-effectiveness they bring to the manufacturing process. While the initial investment in creating a plastic basket mold may be significant, the long-term savings are substantial. The durability of these molds means that they can produce a high volume of baskets over their lifespan, making them an investment for manufacturers. Furthermore, the efficiency of the injection molding process reduces waste and ensures that the amount of plastic is utilized, to lower material costs.

Another advantage is the versatility offered by plastic basket moulds. As consumer preferences evolve, so too does the demand for different shapes, sizes, and designs of plastic baskets. With the ability to modify and customize molds, manufacturers can quickly adapt to these changes, producing a wide range of baskets to suit various needs. Whether it is a small, stackable basket for household use or a large, robust basket for industrial applications, plastic basket moulds can be designed to accommodate a wide variety of specifications.

Moreover, the sustainability of plastic basket moulds cannot be overlooked. With increasing concerns over environmental impact, manufacturers are turning to more eco-friendly molding processes and materials. Some plastic basket moulds are now designed to produce baskets that are recyclable or made from recycled plastics. This shift toward sustainability not only helps reduce waste but also appeals to consumers who are becoming more environmentally conscious.