In the laboratory disposable plastic products are relatively common applications,such as test tube, petri dish, measuring cup, centrifuge tubes etc. Micon Mould has many years of experience in pharmaceutical laboratory (consumables) mould manufacturing.

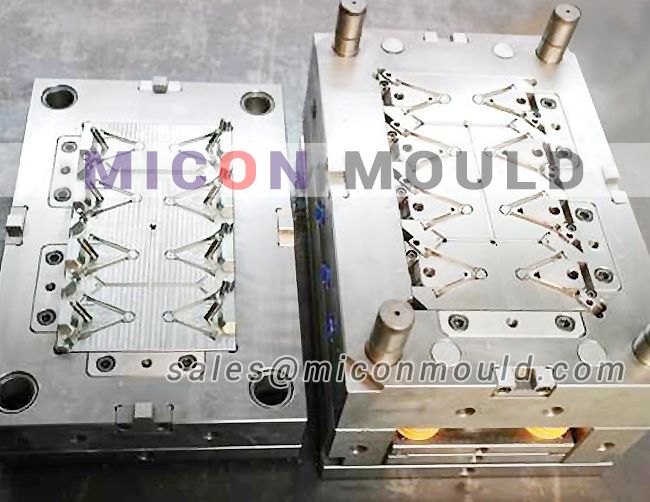

Test tubes, petri dishes and colorimetric cup are mostly made of PS plastics and those items have high concentricity requirments. As we know PS material products can easily get scratches, so it needs supreme grade polishing. Micon Mould uses mirror steel and has artificial polishing to ensure high polish and reduce the scratches.

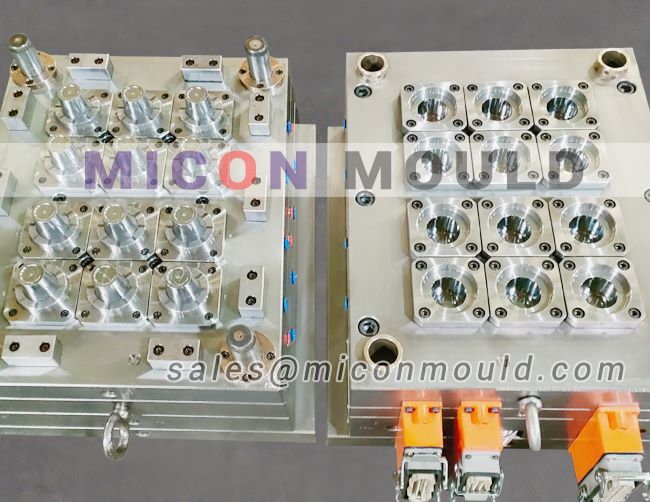

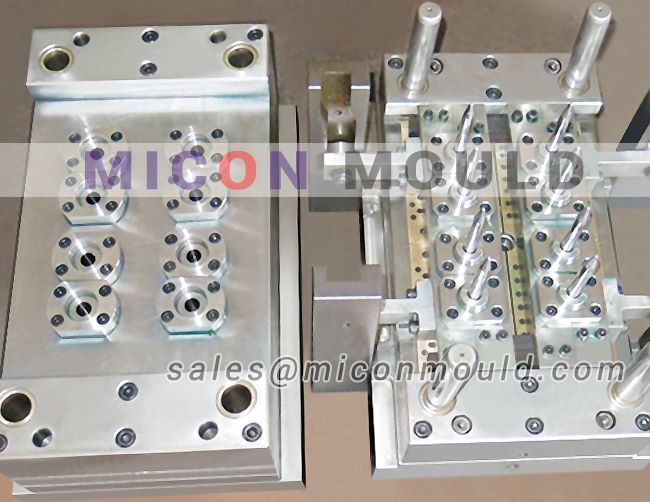

As for medical mould(consumables), the mould dimension should be controlled in precision. For such product, we always use high speed milling machine and some other high precision tooling machine to tool it, the dimension tolerance controlled in 0.02mm.

To make a high quality medical mould(disposable), we need choose the suitable steel material for the medical mould. The common steels we apply into the medical moulds are S136, NAK80, H13, with HRC 45-50. Then the molds can have a mold life from 3 million shots or running for 3-5 years continuously.

let us supply a quote for your next project.

Technical requirements for medical consumable moulds

Selection of molds is very strict, because medical injection molding are all finished in clean room. First, mold materials need stainless steel materials, and need to do matching surface treatment, such as vacuum heat treatment, PVD coating, laser heat treatment and so on. Requirements for medical injection molding are relatively high as precision mold. Because of large number of cavities and large batch size of medical injection molding for medical consumables, hardness and wear resistance of injection molding materials are very high. Hardness of commonly used medical injection molding steel is suitable around HRC48-56. It can ensure strength of mold and good polishing performance.

There are many different design requirements for mold forming structures. There are many transparent parts for medical consumable products. Products should choose hot runners as much as possible to reduce trace of fusion. When using cold runners, soft PVC should minimize size of runners; Therefore, automatic unloading and shearing gates should be used to ensure production efficiency and quality; disposable medical device products have many transparent tubular parts. Pay attention to feeding position of gate and Z-fixing method of dynamic model during design to avoid improper selection of gate position and core fixing method, resulting in uneven material flow during injection molding, which causes core to be elastically deformed, product is uneven or not filled, wall thickness is uneven. Extension tube shape product should pay attention to adopt appropriate exhaust method. Inlet port runner should open overflow well according to molding condition of product to avoid difficulty of molding product due to closed gas. Mold cooling system should adopt multiple sets of separate cooling water channels to reasonably control dynamic mold temperature to control deformation of product. In addition, many medical device products involve problem of push-and-seal sealing. Core of mold forming should be designed to straighten body and not to design draft angle, and to ensure that mold release is normal without strain, so that design cooling should be uniform and provide a higher mold temperature, core surface needs to be treated, and special requirements are required on demolding method to ensure quality and precision of product after injection.

Manufacturing precision of medical injection molding is high as precision mold, because products are in contact with blood and liquid medicine entering human body. Injection molding products related to medical equipment are definitely not allowed to have existence of burr, and many of them are directly matched by plastic parts to achieve sealing and pressure resistance effect, multi-cavity product compatibility requirements. So processing precision of mold core is extremely high, and machining precision of some cores is less than 0.005mm. Surface of mold core is required to ensure that Ra value is 0.20 or more. These precisions have basically reached high manufacturing precision of imported precision equipment. Protection and special handling are required on polishing process of mold.

In general, there is not much difference in structure between medical injection molding and traditional mold, which is mainly reflected in control of processing technology and processing precision.

Advantages of Medical Injection Molding

There are numerous reasons why manufacturers rely on medical plastic injection molding as a go-to method for producing medical devices:

Precision and consistency: Injection molding medical plastics allows for tight tolerances and repeatable dimensions, essential for components used in diagnostics and surgeries.

Scalability: Once a mold is built and validated, medical injection molding companies can produce millions of parts with consistent quality.

Design flexibility: Complex geometries, microfeatures, and integration of multiple functions into a single part are all possible with molding.

Material performance: From rigid to flexible, clear to opaque, a vast material selection supports both performance and regulatory needs.

Cleanroom compatibility: Many parts can be produced in ISO Class 7 or Class 8 cleanroom settings, helping to meet infection control standards.

Cost-effectiveness: For high-volume production, the per-unit cost is significantly reduced, especially when automated handling and inspection are implemented.