Many plastic cutleries in the market, such as plastic spoon, plastic knife, plastic fork and plastic spork. Micon Mould is a professional cutlery mould manufacturer, supply high quality mould to make different kinds of plastic cutleries. Our fork mould, spoon mould, knife mould etc, all are highly praised by our clients.

As the cutlery mould manufacturer, we pay attention to the reasonable requirement, so according customer's production requirement, injection machine specification and customer's invest ability, Micon Mould can help customer chose the suitable mould cavities and maximize their production benefits.

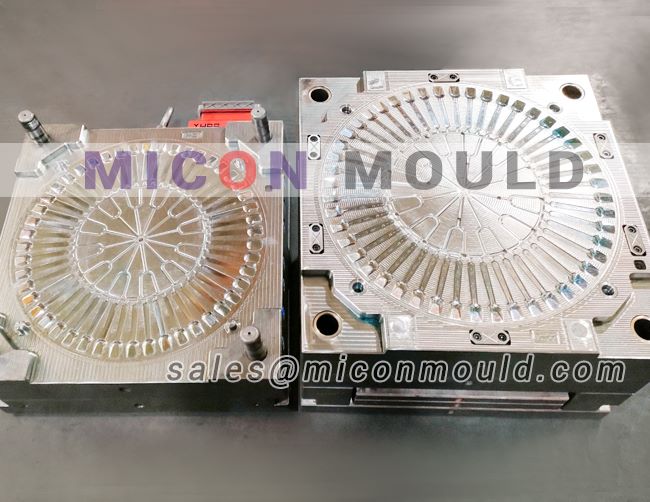

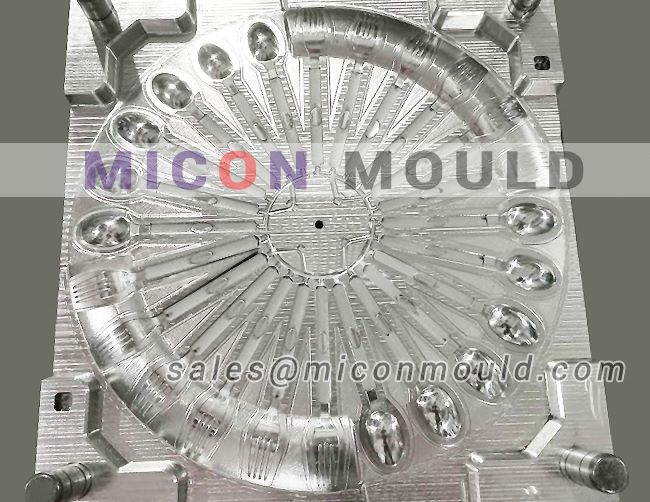

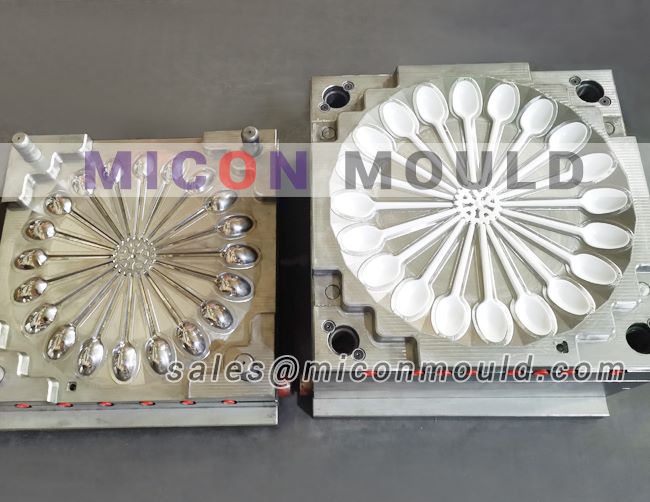

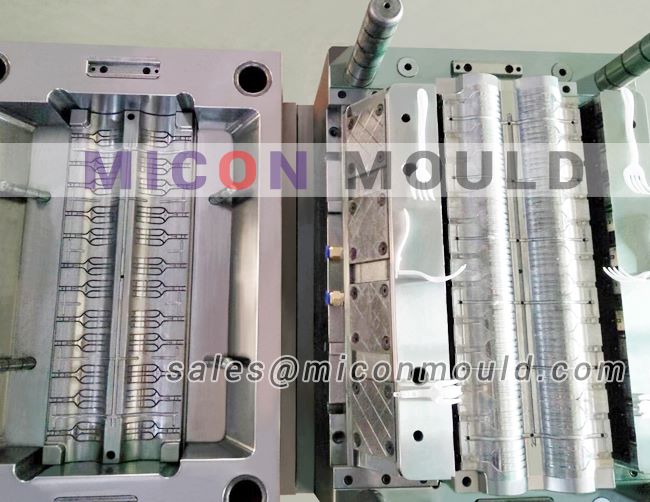

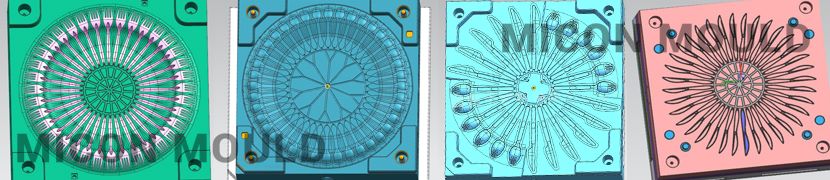

We offer plastic cutlery mould such as 16 cavity, 24 cavity, 32cavity, 48cavity for plastic spoon mould, plastic knife mould, plastic fork mould, plastic spork mould. evenly arranged mould cooling water, can run with cycle time of 10 seconds.

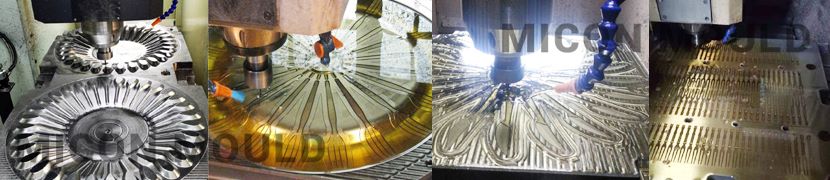

Good mould quality is also very important character of us. Mould quality is also a guarantee for customer's production. Cavity and core, we choice H13 or S136 steel, hardness 45-50HRC, the mould processing will need high speed engraving, high speed milling machines etc, mould life can reach 3 million shots.

Our mould also is diversity. provide cold runner and hot runner to customer choice. According to the customer's injection machine, circular arrangement or fan-shaped arrangement or square arrangement. Using pin point gate, hot runner system or semi-hot runner. If the cutlery mould designed as round shape, it could use semi-hot runner. For spoon fork knife products, it has high requirements on product surface, so the mould polish is very important.

About spoon fork knife design, we should pay attention to product design, at the edge of each product, we should make R angle, otherwise it will be easy hurt mouth. Product weight just mean the cost of the each product, the product weight must as light as possible. If the same products need to be stacked on top of each other to reduce transportation and packaging costs, then the product design must ensure that the superposition effect.

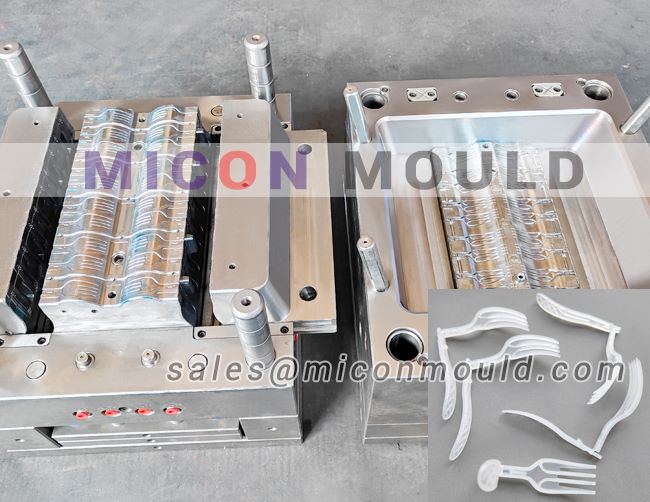

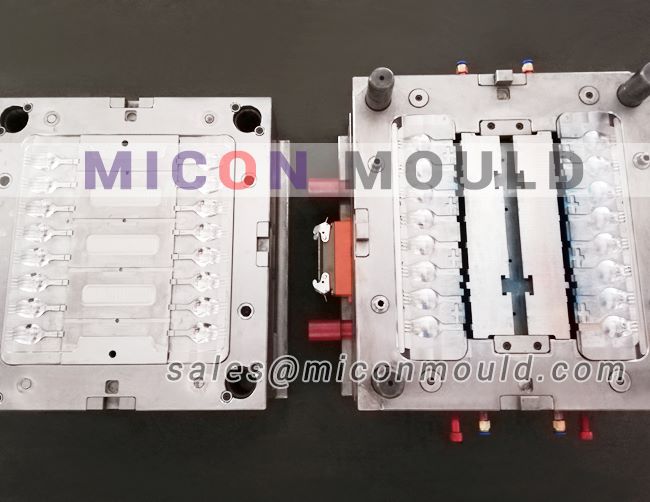

For folding cutlery mould, there need add slides on the mould halves. The folding cutlery moulds are more complicated and difficult than common cutlery moulds.

Before shipment, each mould sold is tested, repaired, polished or adjusted if necessary, and then tested again to ensure its good working condition. Customers are invited to witness the last mould test in person, or, alternatively, receive a sample of the last mould test together with a picture of the open mould, for final approval before dispatch of the mould.

We look forward to becoming your reliable partner.

When You Need Cutlery Mould, Please Feel Free To Connect With Me, We Can Offer You The High Quality Mould With Reasonable Price.

Micon Mould Is Professional Manufacturer Of Cutlery Mould

The steel used for cutlery mold

Cutlery mold is widely used in daily use. Spoon mold, fork mold and knife mold are the most used in disposable tableware. The requirements are also relatively high, the parting surface must be perfect and there must be no flashing, and the surface effect must be good. Long life, steel is one of the keys. In the process of manufacturing cutlery mold, the commonly used mold steels are 718/S136/H13/2738 etc. H13 mold steel has almost become the most commonly used cavity material for plastic cutlery molds.

1. plastic cutlery mold steel

H13: suitable for PP, PS plastics, hardened to about HRC 45-50.

2. Corrosion-resistant mirror mold steel

S136: suitable for mirror molds, high acid resistance after quenching, suitable for PLA, PSM plastics, can be hardened to about HRC 40-45, generally used to make transparent cutlery molds, the mold life can reach 1.5 million shot life.

The gate design of cutlery mold

The location of the gate is of importance with respect to the way in which the plastic flows into the mold impression. Other factors have to be taken into consideration when choosing a gate location, it must be apparent that the positioning of the gate must be determined relatively early on and before the design build-up has started. If the forks, spoon, and knife component is to be conventionally fed, i.e. non-hot runner, the gate location options are further restricted due to the limitations of the two-plate mold design. Restrictions exist because of the necessity of having to gate on a single plane about the mold split line. When confronted with gating requirements outside the scope of the two-plate design,the mold designer has the choice of selecting either the three-plate or the runner-less mold design formats in order to achieve the desired gate position.

The cycle time of cutlery mold

About the cycle time, a complete cycle is: mold close — injection — cooling ( charging at the same time) — mold open — ejection — mold close.

Normally, the machine dry cycle (mold open-ejection-mold close) takes about 3 sec, the injection will take about 2 sec. rest time is for cooling, spoon with 24 cavities, about 8-10 sec for cooling is normal.

So in total cycle time, 15-18 sec is normal cycle time.

Biodegradable Cutlery Mould Manufacturer

PLA is polylactic acid which is made from corn starch. It is a bioplastic that is both compostable & biodegradable.

PLA is very unique material as it is made from corn and not from petroleum. Regular plastics are made from petroleum while PLA is made from corn based resins which makes PLA non toxic and annually renewable resources. PLA is very environmentally friendly material since it is made from renewable resource – Corn. Plastics products may take thousands of years to degrade while PLA products biodegrade within 180 days in a composting system.

The PLA clear products are heat resistant to 110 degrees Fahrenheit. So, PLA products are good for cold products. PLA is not microwave safe, but PLA is freezer safe.

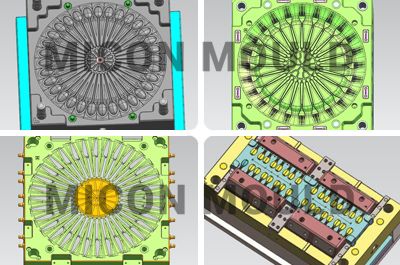

Micon Mould are experienced in manufacture PLA cutlery mould(spoon, fork, knife), PSM cutlery mould (spoon, fork, kinfe). The biodegradable cutlery mould can be designed in round and rectangle shape, Semi hot runner and cold runner.

Cavity and core steel: We can use DIN1.2316 or S136 antirust steel for PLA cutlery mold to sure the long mold life and prevent corrosion and rust. After heat treatment, the hardness can reach HRC45-50.

Cavity amount: According to the production demands for customer, We have done PLA cutlery mould 12 to 64 cavities.

Mould design: We can make the most suitable mould design according to the specific product and your injection machine. Uniform cooling water distribution. Our designer employed from the experienced workers, they have rich experience in the biodegradable cutlery mould design.

Runner system: We can use fully hot runner, semi hot runner for the PLA cutlery mould. As fully hot runner can save the runner plastic material.

Plastic Foldable Cutlery Mould Expert in China

Foldable cutlery allows the consumption of yogurt, ice cream, jelly, salad, noodles, porridge and other foods on the go. Dessert PP foldable spoon can be used for sweet, foldable dessert spoon is very practical. And the most important is the folding design, the spoon can be placed in the lunch box, that doesn't account for space, so foldable spoon will not only convenient for you but also give you a safe food experience.

As a skilled plastic mould company, Micon shows you the process of making foldable spoon mould, folding fork mould and foldable spork mould.

Product design should be reasonable, if some structural cannot be done by injection molding, it must be modified. Also a novel design will be popular in market. Combined with the parameters of the injection molding machine, we give an optimal solution for customers.

Next is the design of the cooling. This is related to the injection cycle. An excellent cooling system can guarantee short cycle and high output. We regulate the temperature with very strategic cooling line placement and coverage. On larger more critical projects, additional time is invested in thermal analysis for cooling line optimization.

Simply, our process is:

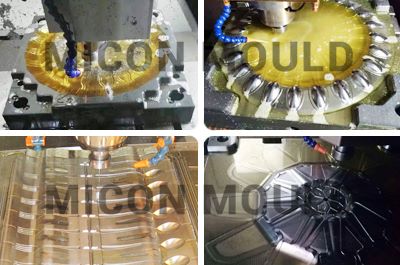

1. Checking the drawing or sample, then making the 3D product design and mould design, later sending to customers for confirmation;

2. Cutting the mould steel, and inspecting;

3. Rough CNC Machining on cavity, core, insert, slider, etc.

4. Gun drilling for heating or cooling system;

5. Heat treatment;

6. Finishing Machining on cavity, core, insert, slider, etc.

7. Re-checking the machine working;

8. Polishing the mould surface;

9. Mould Assembling;

10. Testing the mould, and sending the samples by express to customers for checking;

11. If the samples need to amend, we will re-correct the mould and re-test, until get the satisfied product.