Plastic crate is widely used in storage, assemble, transport. Saving cost, improving efficiency, convenient and easy clean.

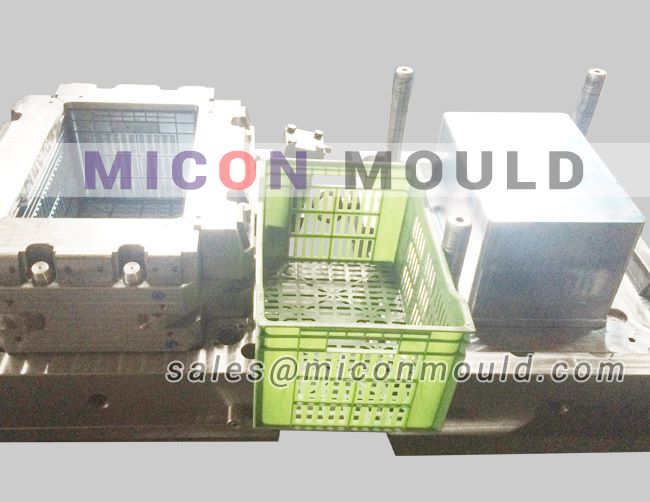

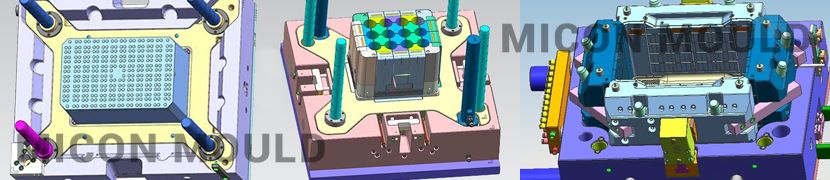

Micon Mould is a China crate mould manufacturer, we has developed more than 100 sets various crate moulds such like, beer case mould, spare parts box mould, storage box mould, milk crate mould, fish crate mould, bread crate mould, collapsible crate mould…

A, do you need a high production performance crate moulds?

B, do you need the automatic ejection function for the cola bottle crate mould?

C, do you want to use the recycled plastic material to molding the one-time using crate?

If you need all these question to be solved and clarified, please come to Micon Mould for crate mould and plastic crate molding solutions.

1, How to make a long life running crate mould?

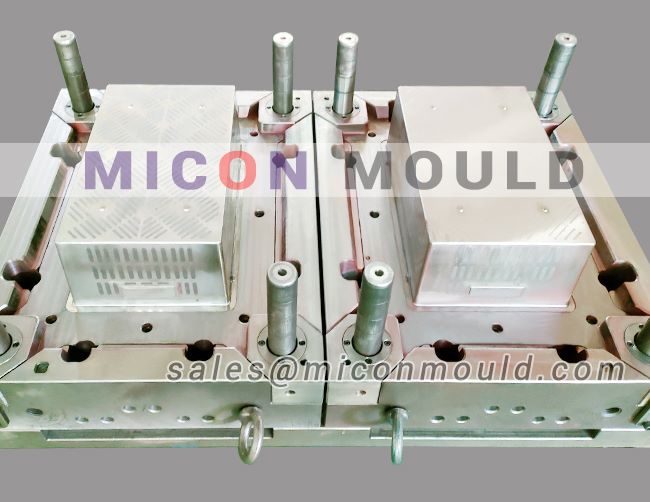

A, Choose the correct steel for mould base and mould main steel. to use a pre-hardened steel with HRC bigger then 33 for mould base and choose the correct steel or material for the durable mould components.make the correct harden treatment to each steel piece and make the steel hardness controlled, you can not make it too hard.And then before shipping, can make nitriding for the sliders. Then this mold can have a mold life from 1Million shots or running for 3 years continuously.

B, To make the best optimal cooling effect, for durable plastic crate mould

We should connect the water channel input and output as many circuit as possible. That is mean to make the crate mold with more separate cooling connections.

For the crate mould core, design the cooling channel up to surface 15mm below the molding surface. And the diameter of the crate mold cooling channel should be more than 12mm diameter, so that the water can run flow smoothly in the channel while take away the heat from the core.

For the crate mould sliders, also, make the cooling channel more close to the crate molding area.

For the crate mould cavity cooling, also should design the best cooling for cool down the hot runner tip area.

By doing the above mentioned design of cooling channel, you can reach a standard crate molding cycle time around 45 to 50 seconds.

C, Plastic crate mould design is very important, it is better to use a mechanical system onto the crate mould ejection, in this way, you can make the ejection action when the mould opening. Of course, maybe your machine can work with the 2 hydraulic acting in the same time, then you can do the ejection when the mould opening.

2. How to use high-speed injection to run crate mould

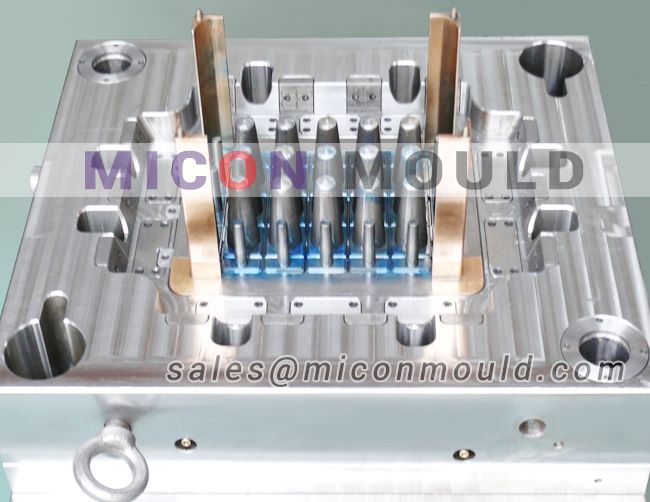

A, Good plastic material filling system requires a special auxiliary molding with hot runner system, because the production of durable crates requires low melt index HDPE material, such as melt index of 4 or 6, and so on.

B, Ensure that the cooling system achieve the best results. To produce durable crate mould, the mold must be the largest cooling circuit design optimal molding surface. The crate mold must use tempered steel material with excellent cooling water.

C, When using high-speed injection molding machines to run the crate mould, the injection screw speed (RPM) must be greater than 350. Most turnover box manufacturers in the world use accumulator to improve the melt injection speed.

D, Plastic crate mould design also is very important. Ejection mode crate mold is preferably designed as a mechanical automatic ejection system, so that when the mold is opened the crate made out. Of course, if the injection molding machine can be equipped with two hydraulic drive machine for automatic ejection, the mold ejection action can be more smoothly.

E, For different types of mold, if want to achieve high-speed operation. The mold must be highly accurate and accessories must have an accurate guide function…otherwise the dies can not have high-speed operating performance.

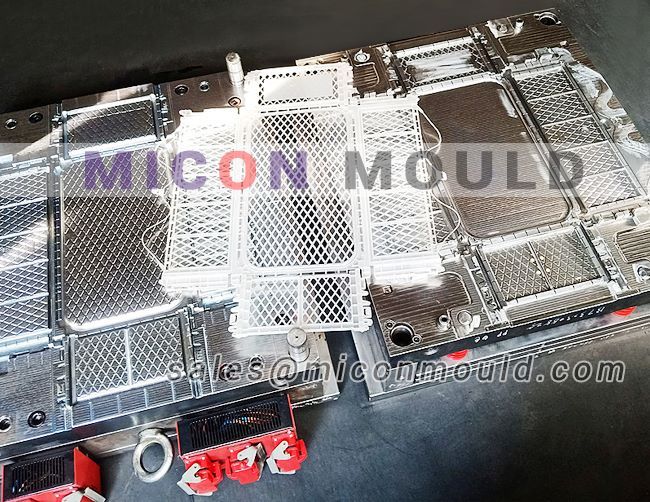

3. The exhaust system of the plastic crate handle part:

The handle exhaust is a very important issue, because when the crate overloading, the handles at both sides are the stress points that bear the load. If the exhaust of the 2 handles not good properly, will leave a visible welding seam, the product is very easy to be damaged.

Plastic crate mould is widely used in storage, assemble, transport. Saving cost, improving efficiency, convenient and easy clean. If you have any interesting , please feel free to contact.

Design Points For Crate Mould

High efficiency points for crate plastic molding:

A. In today’s mature market, facing cost transparency, there must be innovation in the production of mold technology to fill system, special hot runner system assisted molding, so cost of plastic crates will decrease in production efficiency, HDPE is recommended on selection of plastic materials. Material melt index is preferably around 6.

B. Crate mould must have a screw speed of more than 400 on selected injection molding machine. Mold and product release systems mean a return on benefits.

C. Circulating cooling system achieves optimum results, so injection speed may be as high as 800 mm/s (set speed) when injecting plastic crates. And given cooling properties of melt, a suitable cooling system must be available at the beginning of injection. Therefore, production of crate plastic molding must use more than 2 times of quenched and tempered steel materials, so that crate mould can stand test in high efficiency production.

D. Crate plastic molding must have high-precision mold clamping, parts adopt DME standard, insert and guide prevent deformation and misalignment, so choose reasonable guiding design to improve wear resistance, reasonable insert material to improve life of crate plastic molding in high efficiency process.

E. Ejection mode of crate plastic molding is preferably designed to automatically eject mechanical system, draft angle is increased as much as possible, so that when mold is opened, ejection is smoother and more efficient, automatic mold release is realized. Therefore, design of crate plastic molding is very important, ejection action at the time of mold opening determines efficiency, thereby reducing cost.

F. Bronze is inlaid on necessary part of mold. Best features of bronze help mold to cool quickly, which helps to increase efficiency of mold by more than 2 times.

Foldable Crate Mould Manufacturer in China

Micon Mould Is Crate Mould Manufacturer In China

Micon Mould is plastic crate mould manufacturer china, supply various dimension and type crate mould. With the characteristics of smooth surface, durable, good loading capacity.

Plastic crate molds classification

Collapsible crate mould; bottle crate mould; industrial crate mould; vegetable crate mould; fish crate mould; milk crate mould; storage box mould.

Crate molds technical point

1. choose the correct steel for mould base and mould core & cavity steel. Control the hardness of each piece of steel material, it can’t be too hard

2. the moving area and guiding system of plastic crate mold must be processed by high precise machine. Any hand working is not acceptable.

3. Plastic crate mold exhaust system at the handle area is a very important subject, because when move the loaded crate, the handles area is the biggest force focused. If mold exhaust system at the handle area is not good, it will leave a visible weld, the product is very easy to damage from this point.