Commodity mould refers to the production of moulds used in the manufacturing of various consumer products such as household appliances, kitchenware, toys, and other plastic and rubber products. Commodity moulds are designed to meet the specific requirements of the product being manufactured and are typically made from high-quality materials such as steel or aluminum.

Nowadays, plastic commodity products are seen everywhere. With the increasing number of the plastic household products, commodity mould is also becoming more and more popular.

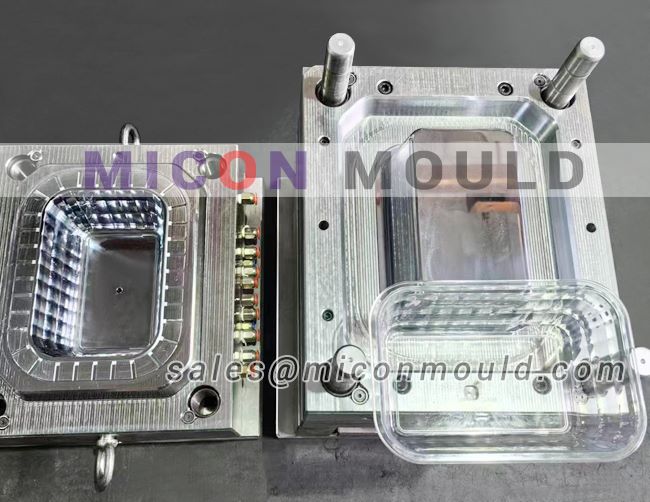

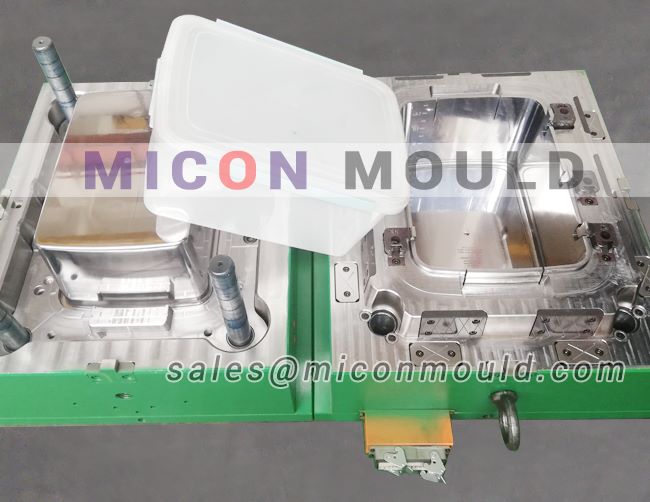

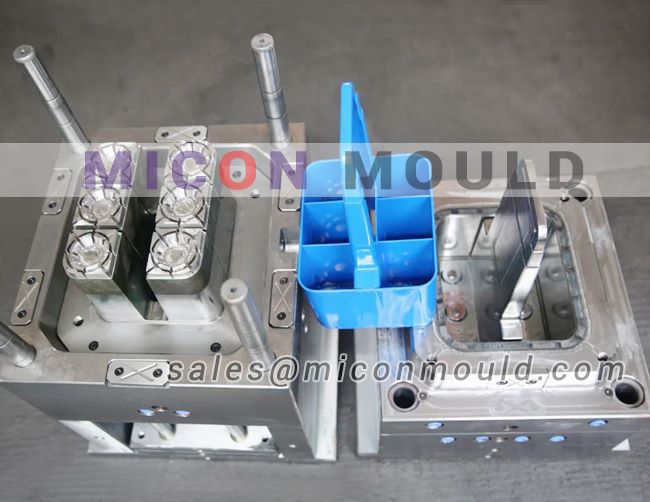

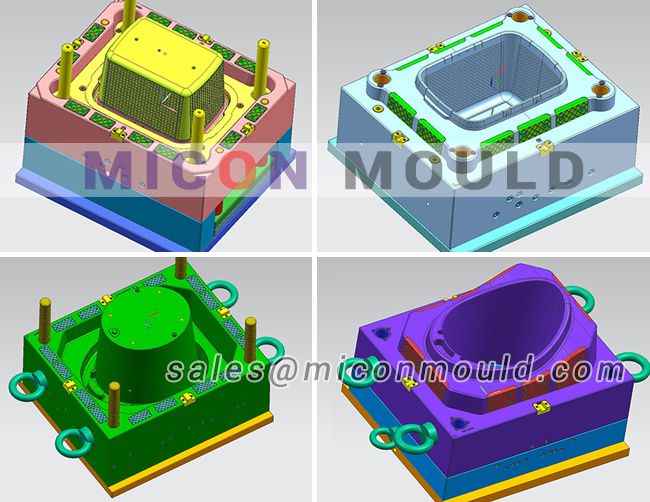

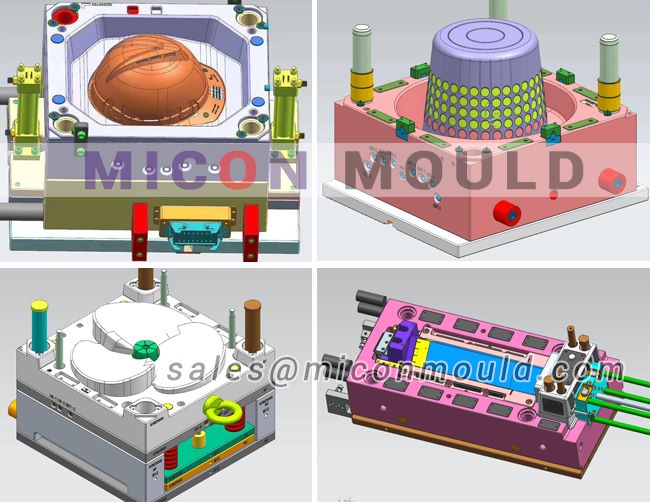

Micon Mould can develop almost any mould in the commodity plastics category. The most commonly developed moulds include laundry basket mould, basin mould, kitchenware mould, sanitaryware mould, dustbin mould, flower pot moulds, mop bucket mould, plastic furniture mould etc.

During decades of years, our engineers devote themselves to finding good solution of commodity mould for customers, and have won high praise from them. Micon Mould have lots of advantages as below:

a, high precision;

b, tight tolerance;

c, optional cooling;

d, long lifetime;

e, fast cycle time;

f, on time delivery;

With the changing nature of products we offer excellent product designs with reduced weights to ensure our customers to be the most competitive and thus become leaders in the House ware market. most commodity moulds we suggest P20, 718 steel or H13 steel depending on the production requirements and material type.

Optimal quality cooling systems and quality spares to increase the life of the molds. We consider basic principles in mould technology such as analysing the structure plates, ejection system, requirement of hot runner or cold runner, avoiding ejection marks, measuring thickness and placement of the cooling lines for achieving great quality in house ware moulds. The products are made of Polypropylene and require very good surface polishing.

Mould delivery time: These are relatively easier compared to other complex or large sized moulds, some of our moulds have been developed even in 35 days. Depending on the complexity and type of product we can promise the fastest delivery possible from our end.

Want to make a full range of household products to meet market demand? Then contact us quickly, We offer high quality household mould as well as commodity mold solutions.

How to Design a Plastic Commodity Mould?

Conceptualization

The first step in designing a plastic commodity mould is conceptualization. This involves understanding the customer's requirements, such as the product's function, appearance, and performance. We also need to consider the manufacturing process and any potential design constraints. For example, if the product has a complex shape, we need to determine the best way to eject it from the mould without damaging it.

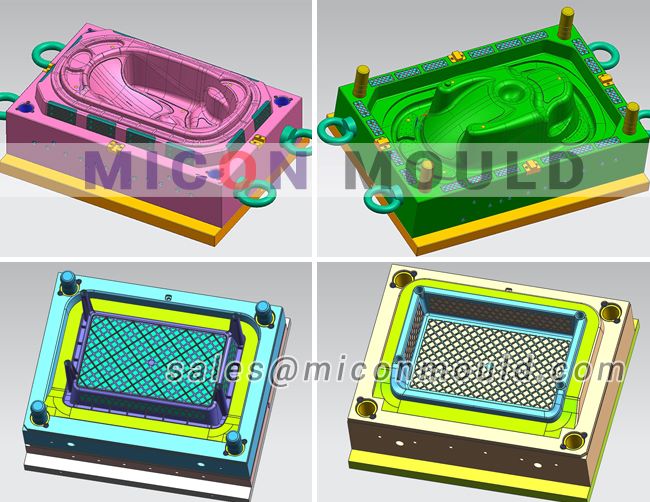

3D Modeling

Once the concept is finalized, we move on to 3D modeling. Using computer - aided design (CAD) software, we create a detailed 3D model of the mould. This model includes all the components of the mould, such as the cavity, core, cooling channels, and ejection system. The 3D model allows us to visualize the mould and identify any potential issues before the manufacturing process begins.

Mold Flow Analysis

Mold flow analysis is an essential step in the design process. This involves using specialized software to simulate the flow of plastic material during the injection molding process. Mold flow analysis can help us optimize the gate location, runner system, and cooling channels. It can also predict potential issues such as air traps, weld lines, and short shots. By analyzing the results of the mold flow analysis, we can make adjustments to the mould design to ensure a high - quality final product.

Detailed Design

After the mold flow analysis, we proceed with the detailed design of the mould. This includes specifying the dimensions, tolerances, and surface finishes of all the mould components. We also need to select the appropriate materials for the mould, taking into account factors such as hardness, wear resistance, and thermal conductivity.

Manufacturing and Assembly

Once the detailed design is complete, the mould components are manufactured using various machining processes, such as milling, turning, and electrical discharge machining (EDM). After the components are machined, they are assembled and tested to ensure that they function properly. Any necessary adjustments are made during the testing phase to ensure that the mould meets the required specifications.

What are the main components of commodity mould?

The main components of a commodity mold include:

Cavity: The cavity is the part of the mold that creates the external shape of the product.

Core: The core is the part of the mold that creates the internal shape of the product.

Sprue: The sprue is the channel through which the molten plastic is introduced into the mold.

Runner: The runner is the channel that distributes the molten plastic from the sprue to the individual cavities.

Gate: The gate is the opening through which the molten plastic enters the cavity.

Ejector Pins: The ejector pins are used to push the solidified product out of the mold after it has been formed.

Cooling Channels: Cooling channels are incorporated into the mold to ensure that the plastic cools and solidifies uniformly and at the correct rate.

Alignment Pins: Alignment pins are used to ensure that the two halves of the mold are properly aligned before and during the injection process.

Venting System: The venting system allows air to escape from the mold during the injection process, ensuring that the plastic fills the mold completely and uniformly.