Plastic chairs and stools can easily get folded, easy to be transported for relatively light weight. The chairs and stools are often used in catering and leisure areas. Plastic chair is one of the most importance furnitures. and be popular with modern consumers.

But now people require the chair is not only about durable. Now more and more people asked for both beautiful and practical, and some even want to change the shape. On this subject, our company can provide you solutions conveniently.

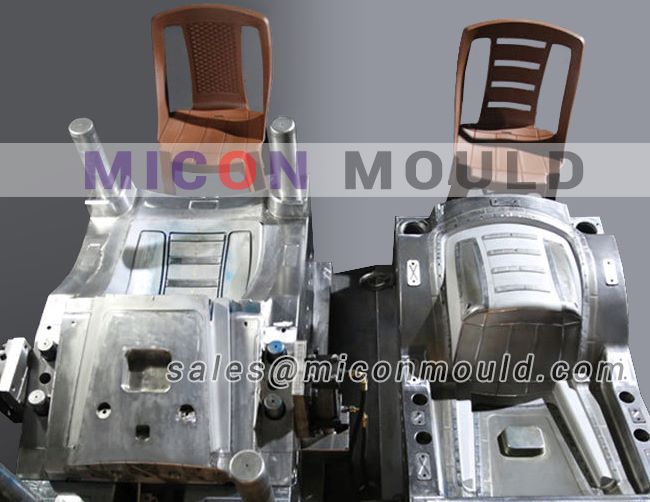

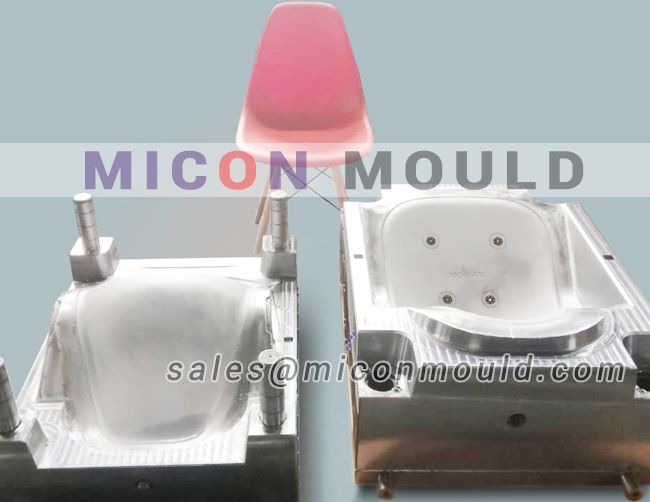

We have accumulated more than 10 years of experience in chair mould production, from the chair mould RFQ, mould design, manufacturing, export them to abroad. The chair moulds that we made have gas-assistant chair, PC chair, arm chair, armless chair, children safety seats, rattan chair etc. Here we'd like to share our experience in plastic chair mould making.

1. Good plastic chair mold design, mould design is the most important step for manufacture a good plastic chair mould, reasonable mould structure, the suitable ejector system, injection system, cooling system, air venting system, guide system.

a. Chair mould injection cycle time: 45-50S.

b. Gate: hot runner big gate to side gate

2. Choose the suitable steel, If the requirement is not very high, recommend P20 with steel hardness HRC33. P20 normally less than 50 million shots.If high requirements, you can use imported DIN2738, steel hardness HRC36-38. DIN 2738 normally 100 million shots under correct operating.

3. About the parting line, we must ensure the mould structure design is reasonable. Using high speed CNC milling tooling machine and mould press machine.

4. About chair wall thickness, sometimes, we need to do is a little thicker in some areas in order to ensure the strength of the chair. But at the same time we have to think carefully about this issue. Because the uneven thickness will make injection result unevenness, and bring uneven cooling which will affect the injection speed and bring shrink marks.

5. Interchangeable inserts. The chair back can be changed by inserts. We can make different back inserts according to the market fashion pattern. The chair arm can be changed by inserts, arm chair and armless chair can be replace the arm inserts.

6. check the chair stackable situation. We have to do analysis for the stacking when making the chair mould design, and need consider the possibility of deformation in the production.

7. Chair mould assembling, the chair mould assembling must be very carefully, check connect of every mould plate; ejector pin, stripper, eject block or slider should move smooth.

A high quality plastic chair mould has short cycle time, long mould life, perfect parting line and high-strength stacking ability as well as reasonable weight. If you want to develop a plastic chair mould for production, please contact us and we will be happy to provide you relevant advice.

If you need plastic chair and stool mould, please feel free to contact.

Plastic Chair Mold Manufacturer In China

There are many plastic chair mold manufacturer in the world, different mold cost, different mold quality. So today, let’s talk about the plastic chair mold in our factory—MICON MOULD.

A. Good plastic chair mold design

Mould design is the most important step for manufacture a good plastic chair mold, reasonable mould structure, the suitable ejector system, injection system, cooling system, air venting system, guide system.

B. Good temperature control for chair mold

1.The plastic chair mold cooling channel quantities as much as possible and the channel diameter as big as possible. the distance between each cooling channel and cavity surface should be same.

2. The injection gate should be cooling very important.

C. The chair weight capacity and weight

First we design this kind chair, the first thing we consider about is its weight and weight capacity. At the begin, we will increase the strength of the bottom part of the chair through putting more strengthening rib. And about the area of the legs, back and cushions, we will analyze the amount of force of every area. So we can know the weight capacity of the chair clearly.

D. Long time chair mold life

1. Choose the suitable steel, 718H is very good steel for chair mold,but because of steel cost, customer use steel P20(28-31HRC) for chair mold.

2. Important to prevent the fash and burr. use high CNC precision machining to chair mold.

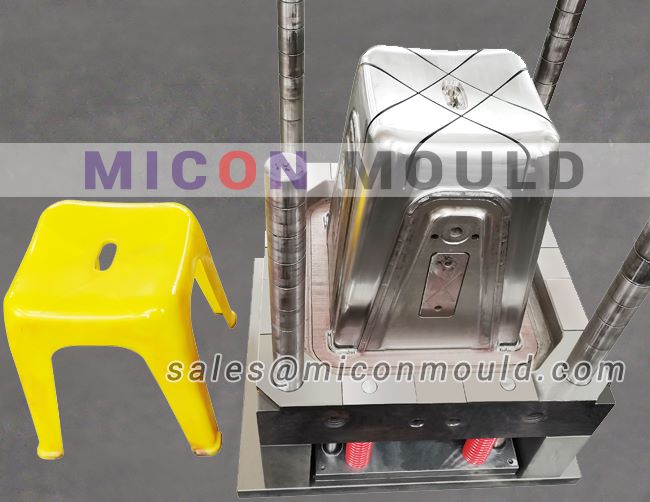

Plastic Stool Mould Manufacturer

Micon Mould is a professional high quality plastic stool mould manufacturer. We can provide you with sample that we have produced for customers and quality case, to provide you with the most satisfactory technical solutions.

1. No. of cavity: Usually the No. of cavity is one because of the big size of the stool.

2. Steel: We provide many kinds of stool mould steel for customer to choose, such as P20, 718, H13 and so on. Good steels are the basis of long life of moulds and high quality of products. All the steels we provide are made by famous steel manufacturers at china and abroad.

3. Heat Treatment and HRC: We commission professional company for heating processing. Different technologies are employed in different components and steels to assure better polish and long usage. The Hardness of core and cavity of stool mould can reach HRC 32-36 after pretreatment.

4. Processing: All components are processing by CNC lathes and the assembly work of stool mould is finished by the makers with rich experience over 10 years.

5. Mould shots: Stool mould shots can reach at least 30 million with good steel, reasonable heat treatment and precise processing.

6. Cycle time: 30-40S

Plastic Stool Mould Manufacturer

Advantages of Using Plastic Chair Moulds

Using plastic chair molds offers numerous advantages, especially in terms of manufacturing efficiency, product quality, and cost-effectiveness.

1. High Precision and Uniformity

● Ensures consistent shape, size, and quality for every chair produced.

● Guarantees tight tolerances, essential for ergonomic and aesthetic designs.

2. Customizability

Allows for a wide range of chair designs, including:

● Different styles (armchairs, stackable, foldable, etc.).

● Surface textures (smooth, patterned, or textured finishes).

● Embedded logos, branding, or special features.

3.Cost-Effective for Mass Production

● Initial investment in the mold is offset by high-volume production.

● Reduces per-unit cost as the mold can be reused for hundreds of thousands of cycles.

4. Fast Production Cycles

● Molds are designed for quick injection, cooling, and ejection, ensuring rapid production.

● Ideal for meeting high-demand scenarios without compromising on quality.