Micon Mould is one of the plastic cap mould manufacturer in China with decades of developing experience. We have already made many kinds of cap moulds, like mineral water cap mould, 3 or 5 gallon cap mould, flip top cap mould, inner cap mould and screw cap mould etc.

About flip top cap mould is very important to make the flip top cap mould well to get qualified flip top caps, is required much for different kinds of flip top caps for shampoo bottle, oil bottle, tomato sauce bottle and so on.

For a good flip top cap mould, it means we could produce good flip top caps with same quality,and the flip top cap mould could run fully automatically with high production efficiency.

For a good flip top cap, when push the flip top to close, there should have sound, when we open the flip top cap to a certain location, it could open fast by itself, this required the butterfly design and also suitable raw material for the flip top cap, when the flip top cap is closed with the bottle, it must have water proof function.

After we know the requirement for a good flip top cap, we could make the flip top cap mould accordingly.

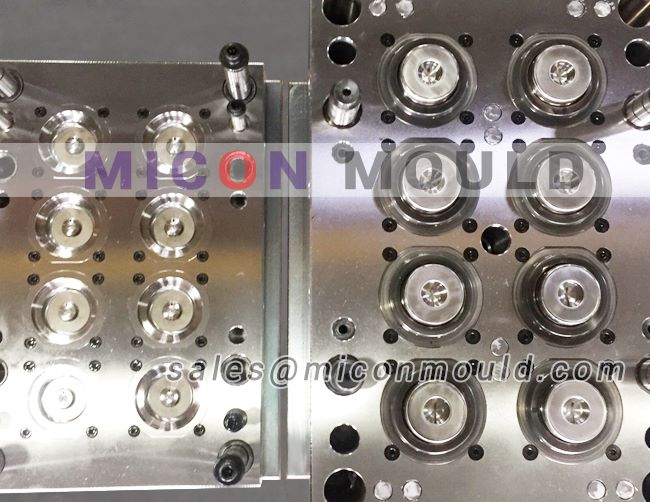

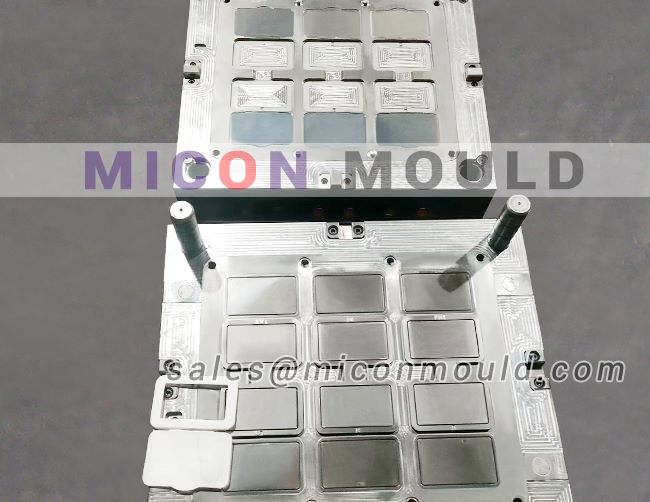

a, flip top cap mould design, the important is for injection gate location choosing, cooling system design and ejection structure design. After the mould design finished, our engineers will have a meeting to discuss about the mould movement to improve the mould structure.

b, flip top cap mould tooling, we use stainless steel material for the core and cavity,which required twice tooling. The tooling accuracy is highly required, both for the matching and butterfly function. especially for the butterfly thickness, it will decide the flip top cap closing & opening stretch.

c, flip top cap mould testing and production. The experience for machine setting is very important for this kind of mould, include the injection speed and pressure setting. Olny when we consider for all the factors, we could get a high quality flip top cap mould.

If you have new projects of cap moulds, please send us details. According to your injection machine, we can suggest the cavity number and select mould steel.

If you are looking for a trustable and professional plastic cap mould making factory, we have 100% confidence that Micon will be your right choice!

Micon Mould is Cap Mould Manufacturer in China

We always pay attention to the technical innovation and development of packaging cap moulds. We have developed and manufactured a variety of plastic cap injection molds with excellent quality and a wide variety of flip molds, beverage bottle cap molds, cosmetic bottle cap molds; At the same time, we are also committed to providing customers with complete sets of cap injection molding solutions, such as: automatic thread rotary injection molding solutions, automatic flip injection molding solutions, strong de-threaded cap injection molding solutions etc.

Cap mould design

We have experienced mold designers using advanced software for plastic cap mould design. The designed plastic mould has the advantages of rapid cooling, high efficiency, easy processing, simple operation and maintenance.

Cap mould steel selection

Since the plastic cap mold works for a long time in a high-speed injection molding environment, the plastic bottle mold must use high-strength die steel. In general, the mold cavity and core of the plastic cap mold are made of S136, which has the advantages of fine polishing, high hardness and corrosion resistance.

Hot runner system selection

Choosing an excellent hot runner system ensures a balanced and stable injection of all gates in the mold to produce a better plastic cap. Taking into account the convenient replacement of later mold-related accessories, we can provide a variety of brands of hot runners for customers to choose.

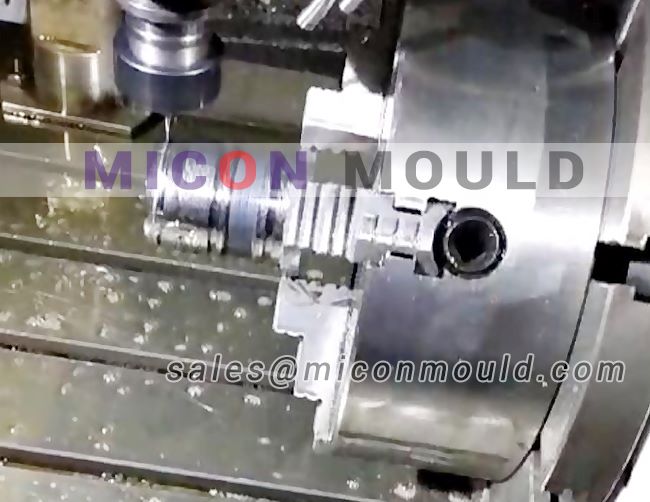

Cap mould making

All mold parts are completed by high-precision lathes, electric sparks and slow wire electric sparks. In order to achieve its accuracy requirements, all of our EDM and slow wire EDM machines are imported from Japan’s Sodick with high tolerance accuracy.

In addition, after each machining process is completed, the template and mold parts must pass the inspection by the quality inspection team before entering the next machining program. This ensures that the accuracy of the mold is met and unnecessary rework time is avoided.

Cap mould test

Prior to shipment, each plastic cap mold was run on machine to further test its quality to ensure long-term efficient operation of the mold after it reached the customer's facility.

Plastic flip top cap mould design and manufacturing

Relying on strict quality standards and strong technical innovation capabilities, we have established long-term cooperative relationships with many customers at home and abroad, and designed and manufactured high-quality flip top cap molds for them.

1. We attach great importance to the bow hinge design to ensure its flexibility and not easy to break.

2. We use Moldflow analysis to simulate the entire injection molding process to ensure high yield of products during mass production.

3. The hot runner system uses German heating components with excellent performance to ensure uniform melt flow and pressure in all cavities.

4. Each cavity independently controls the heat to ensure a uniform temperature.

5. Standard interchangeable mold inserts.

6. All parts are machined with high precision CNC equipment with a tolerance of less than 0.02mm.

7. High-hardness stainless steel mold core and cavity, double anti-corrosion and anti-rust, ensuring high precision and long mold life.

8. Each cavity and core has an independent cooling system that shortens the production cycle.

9. Special water pipe design eliminates water pipe leakage.

10. It is convenient to change the cavity number identification of the cavity and the core, so that the customer can quickly find and replace it correctly.

11. Our mold parts are available in DME, HASCO or other standards to make it easy for customers to find replacement parts on the market. These standards are internationally versatile and easy to purchase and easy to replace.

12. We can provide inspection reports on important dimensions of CMM molds.

13. In-mold automatic flip or automatic flip can be designed according to customer requirements.

14. Mould life exceeds 2 million molds.

Plastic cap mould parting surface

The selection of the parting surface in the process of designing the plastic cap mold is very important. It determines the structure of the mold. Micon Mould suggests that the parting surface of the mold should be determined according to the principle of parting surface selection.

1. Easy demolding: keep the plastic caps stay on the movable mold. The mold release mechanism is on the side of the movable mould. The main cores is mounted on the side of the movable mould, so that the caps are wrapped on the cores. The cavity can be placed on the fixed mold.

2. The mold structure must be simple, so that the mold is easy to be cut and processed. From the viewpoint of simplifying the mold processing, the plastic caps requiring core pulling should be avoided as much as possible in the fixed mold part.

3. Must have a smooth exhaust on cavity to ensure the cap quality. Basing on the cap appearance, the rational use of equipment and molding requirements to decide the parting surface. The plastic closures are plastic bottle caps, there is no requirements on the cover. Because the parts have lateral point-to-heart connection which need a lateral inner core pulling mechanism. If more complicated type, can use quick lateral splitting.

Compression bottle cap mould

Except use injection molding for bottle caps production, there has a new production method that is rotary compression bottle cap machine.

Micon Mould is Cap Mould Manufacturer in China

Plastic caps are favored by more and more manufacturers and people because of their plasticity, low density, high specific strength, high degree of bonding, high chemical stability and diverse appearance. The selection of plastic mould steel has a great influence on the quality of the mould. Therefore, the principle of plastic closure mould generally has the following four points:

1. Fatigue fracture performance

During the process of plastic bottle cap mould manufacturing, under the long-term effect of cyclic stress, it may cause fatigue fracture. Its form has small energy multiple impact fatigue fracture, tensile fatigue fracture and bending fatigue fracture.

The fatigue fracture properties of the mould mainly depend on its hardness, strength, toughness and the content of inclusions in the material.

2. Better high temperature performance

When the mould under a high working temperature, the hardness and strength will be lowered, resulting in early wear of the mould or plastic deformation and failure. So the mould steel should have high tempering stability to ensure high hardness and strength to hold the high temperature.

3. Resistance to cold and heat

Some plastic cap moulds are repeatedly heated and cooled during the working process, causing the cavity surface to be tensile, and with the press-induced the surface get cracking and spalling which increase the friction, impeding plastic deformation, and reducing the dimension accuracy, resulting in mould failure. Hot and cold fatigue is one of the main forms of mould failure. Therefore, for plastic bottle cap mould must have high resistance to cold and heat.

4. Corrosion resistance

Some plastic moulds will release HCI, HF and other strong aggressive gases when working due to heating which corrupt the mould surface, increase its surface roughness and aggravate wear and tear.

For the cap mould, we want to share some technique points:

a. Adopt advanced CNC machine, EDM machine, high speed engraving machine to make sure tight tolerance;

b. Use high grade steel S136, 2316, H13 to guarantee 5million mould life and good quality;

c. Optional water cooling system for fast cycle time;

d. Stable Performance hot runner and temperature controller;

e. Self-lock in order to avoid eccentric of the mould;

f. Interchangeable core insert, it is better for future maintenance when assembly;

g. Multi-cavity for mass production;

h. All cap moulds are automatically eject;