Cable Ties Application

Cable ties can be widely used in household or industrial electrical appliances, auto industry, food packaging, industrial packaging, logistics, agriculture, machinery, construction, boats, ports, fire extinguishers, electricity wires, price tags, large machines, computer motherboards or special industries, etc.

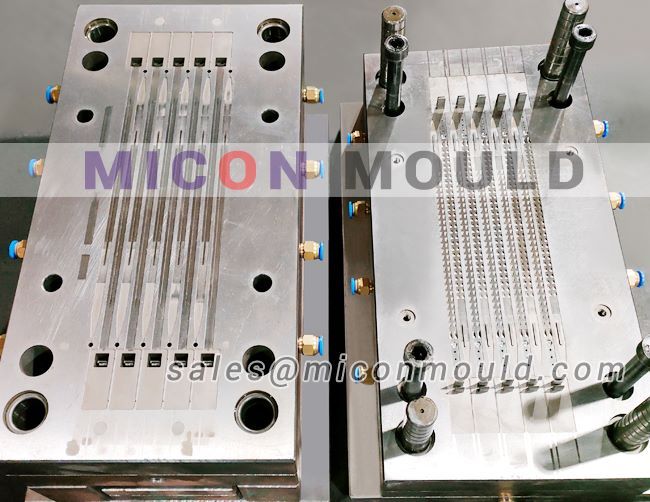

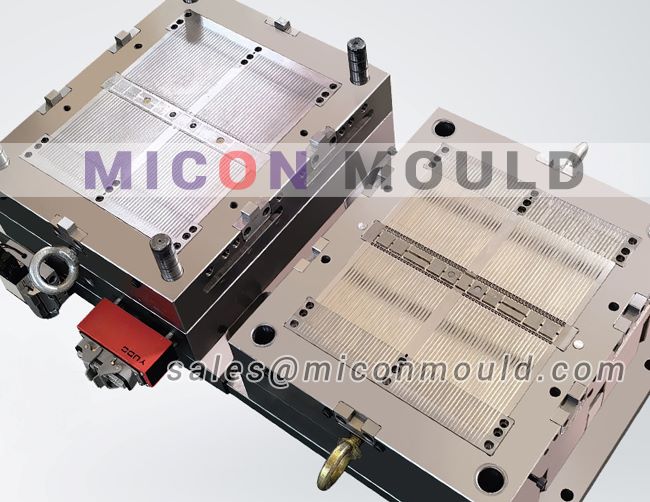

Cable Tie Mould Manufacturing

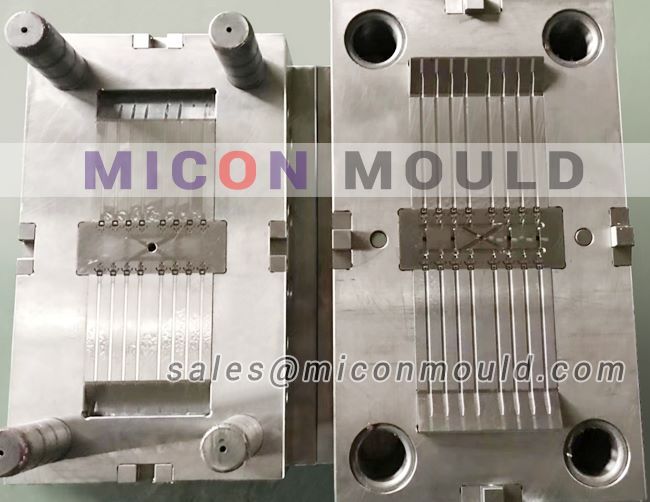

The common cable tie consists of a flexible nylon tape with an integrated gear rack, in order to ensure the serration and tape fit tight and won’t slip, the teeth need to be processed by electric spark, using copper as the electrode, each time at 0.01MM accuracy when processing. We use wire cutting to process the cable tie head and insert them on the mould core and mould cavity which is convenient for maintenance.

Mould Cavity

Because there are many kinds of cable ties with different sizes, we will recommend the appropriate number of cavities according to customer's injection molding machine. At present we have made 12-140 cavities for different sizes.

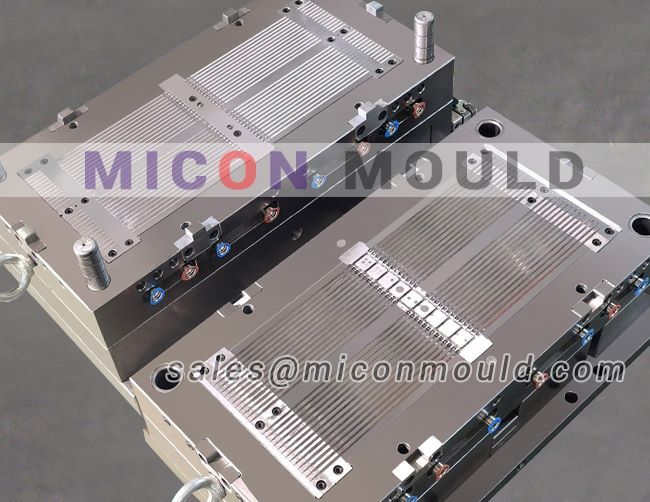

Runner

Usually if customer no special requirements for runner, we will use cold runner for cable tie mould. There requires a higher mould temperature at the beginning of production. It will connect the mold temperature controller to heat the mould.

With the development of the injection molding process, we can also make hot runner cable tie moulds, which will use valve gating system as for the cable tie is long and narrow that requires high injection speed. The machine barrel temperature is relatively high, the ordinary hot runner cannot control the melt material flow, so it needs to be valve gate. Of course the hot runner price is much higher than cold runner mould.

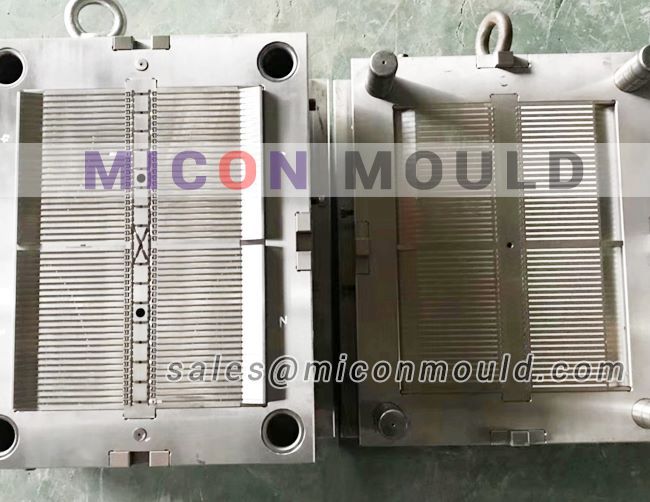

Mould Steel

Usually we use Cr12MoV steel for the self-locking cable tie mould. The hardness can reach to HRC55 after heat treatment. For the cable tie mould, higher hardness, longer mould life. We can also use SKD61 steel which is more expensive in cost.

Product Weight

Since the fierce competition in cable ties market, we can reduce the weight appropriately according to the requirements for the tensile strength.

If any cable tie mould project interested, please don't hesitate to contact us by mail or phone.

Nylon Cable Tie Mould Manufacturer in China

The nylon cable ties are made of UL-approved nylon-66 (Nylon 66) material. The fire rating is 94V-2. It has good acid resistance, corrosion resistance, insulation resistance, and is not easy to age and bear strong. Operating temperature is -20 °C to +80 °C (ordinary nylon 66). Widely used in electronics factories, strapping TVs, computers and other internal connecting lines, fixing of wiring in lighting, motors, electronic toys, mechanical equipment oil pipelines, cable lines on ships, bicycle packaging, and can also be used for agriculture, gardening, handicrafts, etc. Cable tie has the characteristics of fast binding, good insulation, self-locking and fastening, and convenient use.

To get high quality of cable ties, there need best cable tie moulds. We are a professional plastic cable tie mould supplier in China. We can offer nylon cable tie mould with high quality at reasonable price. The cable tie mould steel we use is Cr12Mov (SKD11, 1.2601, 2310), HRC 50-54 after heat treatment, which can withstand long time of high pressure when cable tie injection molding. The comprehensive mechanical properties of Cr12Mov after quenching are much higher than other types of steel, and are widely used in the manufacture of cable tie moulds. The steel has high wear resistance, hardenability, hardenability, toughness, thermal stability, compressive strength, and micro-deformation and excellent performance. Comparing with H13, SKD61, Cr12Mov is the most cost effective way. Mould life 1,500,000 shots under correct operation.

Cable tie moulds commonly are cold runner as it is economic way to produce cable ties. Clients also can choose hot runner according to budget and requirements. We are well equipped with High Speed Milling machine and normal CNC milling machine, EDW with two heads, wire-electrode cutting machines and others advanced equipments.

The teeth and lock system processing for cable tie is very important. Only high accuracy of machining and good steel can ensure the cable ties be tightened smoothly. Simple but effective locking mechanism is basic requirements for zip ties. This requires cable tie mould maker has rich experience and skills to reach no slippage, no deviation, no flash.

What cable tie mould we can make:

Single loop cable ties moulds, heavy duty cable ties moulds, HVAC duct straps moulds, mounting hole cable ties moulds, push mount cable ties moulds, tefzel cable ties moulds, polypropylene cable ties moulds, heat stabilized cable ties moulds, fire retardant cable ties moulds, color cable ties moulds, beaded cable ties moulds, identification cable ties moulds, double-loop cable ties moulds, mounting based for cable ties, wire clip & saddles moulds, cable clamps moulds, twist-on connectors moulds, wing style connectors moulds, printed circuit board supports/spacers moulds, hook & loop cable ties moulds etc.

Benefits of high-quality cable tie moulds

investing in high-quality moulds made from Cr12Mov steel and subjected to advanced techniques offers several significant benefits:

Improved product performance: durable, well-crafted moulds result in stronger, more reliable cable ties that can withstand stress and wear over time.

Cost-efficiency: though the initial investment is higher, high-quality moulds lead to long-term savings by minimizing downtime and defective products.

Faster production: efficient mould design and treatment methods contribute to faster cycle times, enhancing overall production speed.

Sustainability: durable moulds last longer, reducing the need for frequent replacements and contributing to more sustainable manufacturing practices.