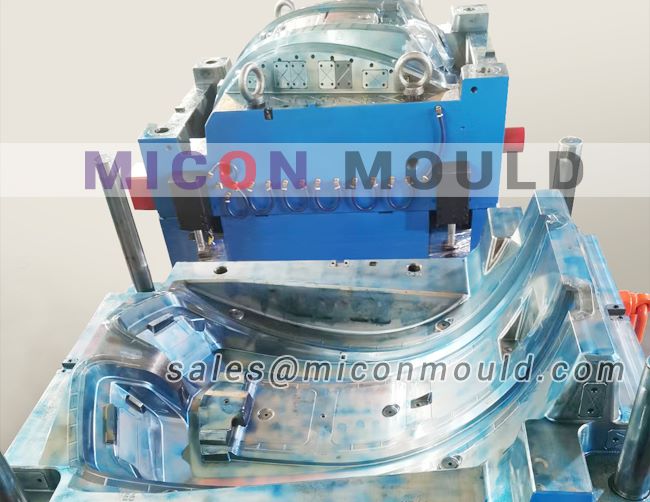

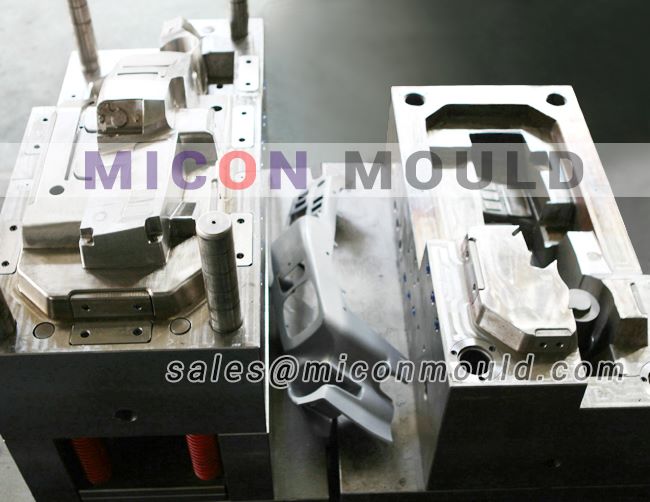

Micon Mould is auto parts mould supplier, offers high quality auto parts mould to automotive industry. Our products include grille mould, bumper mould, car lamp mould, license box mould, brake mould, battery box mould, rear under view mirror mould and so on.

Micon Mould have high precision CNC equipment, dedicated to produce auto parts mould. At the same time of perfect process, we will make the size detection for each processed parts. And match with 3D design drawings to ensure the mould accuracy.

In additional, we attach importance to each step of auto parts mould processing, we will show clients each part in the form of photos and videos, form the raw material controlling, mould processing to mould test and shipment.

With the development of automotive industry, automotive factories prefer environment protection, portable auto parts, we have rich experienced in plastic automotive mould in the past several years. Can offer the best service, from plastic auto parts design, structure design, mould processing, plastic parts injection molding and so on.

Let Our engineers help you analyze a project, and figure out how much the mould costs. Get your project started now!

How Auto Parts Mould is Made?

Auto parts moulds are made through a complex process involving multiple steps. Here is a general overview of how an auto parts mould is made:

Designing the mould: The first step in making an auto parts mould is designing it. This is typically done using computer-aided design (CAD) software, which allows engineers to create a digital 3D model of the mould.

Creating a prototype: Once the design is finalized, a prototype mould is created. This is typically made using CNC (computer numerical control) machines, which use computer-controlled cutting tools to create the mould from a block of steel.

Testing the prototype: The prototype mould is then tested to ensure that it produces parts that meet the required specifications. If adjustments need to be made, the design is revised and a new prototype mould is created.

Manufacturing the mould: Once the prototype mould is finalized, the actual mould can be manufactured. This involves creating a series of cavities and channels within a block of steel that will allow the molten material to flow into the mould and form the desired part.

Finishing the mould: After the mould is manufactured, it undergoes a series of finishing processes to ensure that the surface is smooth and free of imperfections that could affect the quality of the parts produced.

Installing the mould: Once the mould is finished, it is installed into a moulding machine. The moulding machine injects molten material into the mould, which then cools and solidifies to form the desired auto part.

Quality control: After the part is moulded, it undergoes a series of quality control checks to ensure that it meets the required specifications. If any issues are identified, the mould may need to be adjusted or repaired before further production can take place.

Overall, making an auto parts mould is a complex and precise process that requires careful planning, design, and execution to produce high-quality parts.

The Importance of Precision in Automotive Parts Mould Manufacturing

Precision in auto parts mould manufacturing sets the foundation for producing high-quality auto components. Even the slightest misalignment in mould design can lead to defects, inefficiencies, and increased costs. Consequently, manufacturers must prioritize the following:

Advanced Design Techniques

Employing CAD (Computer-Aided Design) allows for intricate designs to be crafted with high precision, whereas simulations can predict the mould's performance under various conditions. This technology should be combined with CAM (Computer-Aided Manufacturing) systems to automate the production process and reduce the likelihood of human error.

Machining and Manufacturing Processes

Precision machining techniques, such as CNC (Computer Numerical Control) machining, are pivotal in producing moulds that fit with utmost accuracy. High-speed machining and electrical discharge machining (EDM) are commonly employed to achieve tight tolerances and fine surface finishes, contributing significantly to a mould's performance.