Plastic utensils mould

plastic utensils mould, plastic cutlery mould, plastic tableware mould

Mould cavity: multi

Mould material: S136, H13

Runner: Hot runner

Mould Life: More than 1.5 million shots

Specification: All size of available

Design Software: UG, CATIA, PROE, OUT CAD

Mould running: Full automaticity

Moulds features: Fine cooling system

Delivery time: 55days

Packing: Wooden case

The steel of cutlery mold

Consumption of plastic cutlery is very huge, especially disposable plastic cutlery. So plastic cutlery mold needs with long life to meet the production quantity request. Micon Mould uses H13 to produce plastic cutlery molds. H13 steel after vacuum quenching hardening treatment, its hardness can reach 48HRC to 52HRC. The mold life can exceed 2 million shots.

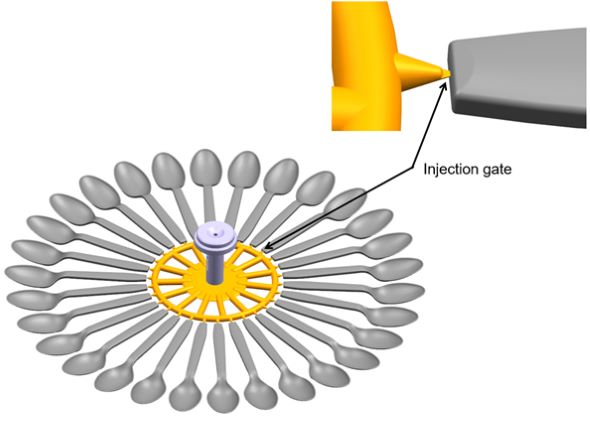

The runner system of cutlery mold

plastic cutlery mold can be made with a cold runner or hot runner system. For some large quantity cavity numbers, Micon Mould suggests making the cutlery mold with one point big gate hot runner system to easily make the injection molding. Plastic cutlery molds often use round shape and sector shape runner to ensure each cavity can get the same injection pressure during injection molding. This kind of runner design can offer excellent runner balance.

The plastic raw material of cutlery mold

Most of the plastic cutlery is made by food safe grade PP material and food-safe-grade PS material. Plastic cutlery made by PP is softer than PS material.

Tooling process required for cutlery mold

After mold steel purchased, we will do the CNC milling tooling and drilling holes for the mold. CNC milling tooling is a process of rough tooling.

After the rough tooling, the mold cavity plate and core plate will be done the vacuum quenching hardening treatment to make the steel hardness to 48HRC to 52HRC. With this hardness, mold life will be more than 2 million shots. As the steel with high hardness, the following precise tooling will take a long time. So cutlery mold production can not be quick. CNC engraving tooling is the cutlery mold‘s main precise tooling.

After CNC engraving tooling, cutlery mold will be assembled and make for the first time mold test. At first, the mold won’t be polished, after there is no problem, the mold will go on the polish job. At last, when the customer confirms to ship the molds, we will do the last test to ensure all process is ok and then packed for shipment.