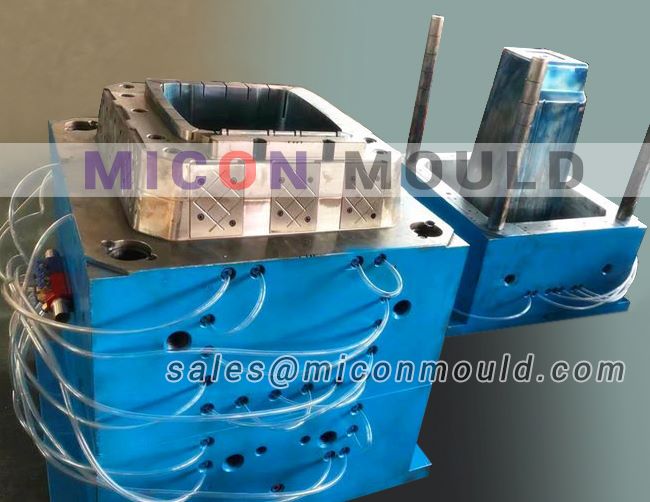

Plastic trash can mould

We have 32L, 45L, 60L, 80L, 120L, 240L and other different sizes of trash can molds, and inlaid beryllium copper at the top of the core and the edge of the cavity to speed up the cycle and improve the production efficiency of the classified trash can. Its product features pedal-operated, hangable models, household upper and lower, medical, and ordinary.

Classification trash can mold quality points

Short injection molding cycle, high output per unit time

The CAE software is used to analyze the temperature distribution during the molding process, and the design of the cooling system is enhanced at the highest temperature to effectively shorten the cooling time and speed up the cycle.

The molding system has strong stability and high yield.

The runner system has reasonable design and high yield. The hot runner adopts German heating elements and is balanced and stable.

The product has a uniform wall thickness, is not eccentric, and has a long die life.

Precise mold assembly, high dimensional accuracy, and reasonable design of the clamping mechanism

Suitable for low melt fat number (MFI) plastic injection molding, durable products

The mold strength is good, the force is balanced, the molding system pressure is low, suitable for low-melting index plastic injection, the product has strong toughness, resistance to falling and anti-aging.

Processing equipment description: Our company uses CAD / CAE / CAM computer system software, high-precision CNC machining center, CNC EDM, wire cutting, large CNC machine tools and other processing equipment, with a full set of equipment and good peripheral supporting resources to ensure the mold Low cost and fast processing capability.

Trash Bin Mould steel: p20 universal pre-hardened steel, good cutting performance, good weld repair performance, suitable for electrolytic corrosion operation.

Main use: It is used for large plastic molds and mold bases with high requirements.

718 pre-hardened, high hardenability, good polishability, high hardness pre-hardened steel, good machinability.

Plastic material: PE

Mold cavity number: single cavity

Die life: 100,000-200,000 times.

Runner: hot runners and cold runners, depending on customer requirements.

Uses: Used for injection plastic molds, which mainly include a cavity and a core with combination plates. Coordinated changes in mold cores and cavities and auxiliary forming systems. It can process series of plastic parts of different shapes and sizes.

Cooling system: Optimize the design of circulating water, improve production efficiency and reduce customer production costs.

Medium-term treatment: tempering and improving hardness.

Post-treatment: Nitriding (low nitriding temperature, low deformation, high surface hardness (greater than HV850) and wear resistance no longer required for quenching)

Transportation of mould: The mold must be installed before the mold is shipped, the packaging is strong, rust-proof, logistics and transportation

If you have any needs in this regard, please contact us, we focus on providing customers with a suitable trash can mold solution.