Plastic foldable cutlery mould expert in China

Foldable cutlery allows the consumption of yogurt, ice cream, jelly, salad, noodles, porridge and other foods on the go. Dessert PP foldable spoon can be used for sweet, foldable dessert spoon is very practical. And the most important is the folding design, the spoon can be placed in the lunch box, that doesn’t account for space, so foldable spoon will not only convenient for you but also give you a safe food experience.

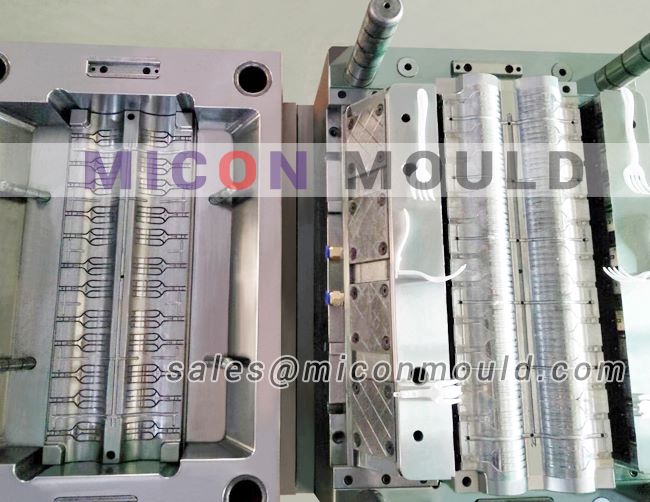

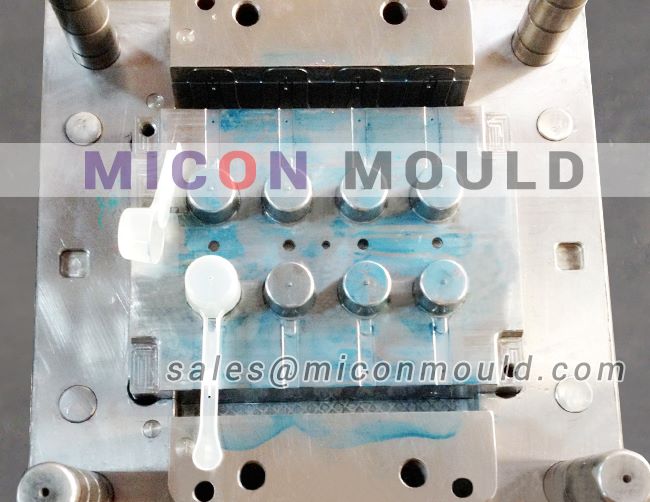

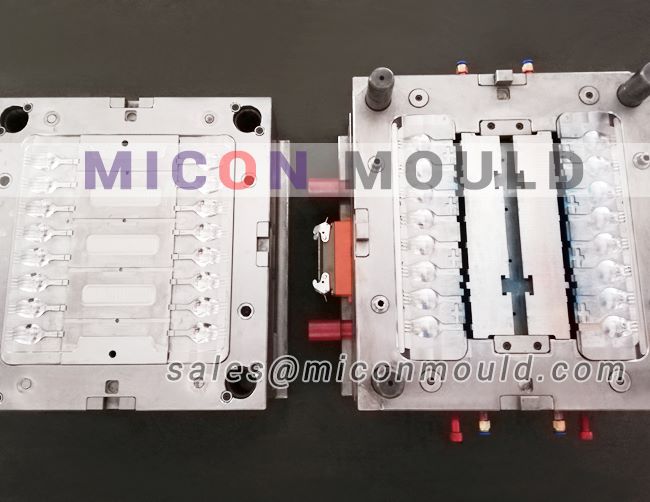

As a skilled plastic injection mould company, Micon shows you the process of making foldable cutlery mould, folding spoon mould and foldable fork mould.

It is important to know what steel and how many cavities needed. If have no clue, it is better to let us know injection machine parameters, then we can suggest maximum cavities based on the spoon/fork/spork dimension and weight. Plastic cutlery spoons require high yields to generate revenue. Therefore, the mould must ensure long life, short cycle, and product with light weight. We usually use H13, S136 stainless steel, these two materials are high hardness, can guarantee more than one million life. Customers can send cutlery project to my email: miconmould@gmail.com, we will send quotation as soon as possible within 24 hours. Also you can contact my Wechat/Whatsapp: +86 153 0676 1345 directly, telling me your thoughts.

Another very important thing for foldable spoon mould making is the design. Product design should be reasonable, if some structural cannot be done by injection molding, it must be modified. Also a novel design will be popular in market. Combined with the parameters of the injection molding machine, we give an optimal solution for customers.

Usually we use a 1-point hot runner, and some require more points. Of course, the cost is higher.

Next is the design of the cooling. This is related to the injection cycle. An excellent cooling system can guarantee short cycle and high output. When you are creating a part using molten metal, you need to properly cool the part before removing it from the cavity. Removing the part too soon can change the shape of the part and compromise its structure. Some die casting companies just place a simple cooling circuit in the cavity block to save cost in design and tool manufacturing. We regulate the temperature with very strategic cooling line placement and coverage. On larger more critical projects, additional time is invested in thermal analysis for cooling line optimization.

Simply, our process is:

–Receiving the prepayment from customers

–Checking the drawing or sample, then making the 3D product design and mould design, later sending to customers for confirmation (if the complex mould, we will do mould flow for easier making)

–Cutting the mould steel, and inspecting

–Rough CNC Machining on cavity, core, insert, slider, etc.

–Gun drilling for heating or cooling system

–Heat treatment

–Finishing Machining on cavity, core, insert, slider, etc.

–Re-checking the machine working

–Polishing the mould surface

–Mould Assembling

–Testing the mould, and sending the samples by express to customers for checking

–If the samples need to amend, we will re-correct the mould and re-test, until get the satisfied product.

High quality moulds not only ensure the quality of injection molded products, but also to provide customers with an important basis for system solutions.

Features and advantages

–optimize temperature control

–cooling waterway profile design

–easy to maintain

–optimized steel with high-precision processing

–long life, super durability and high performance

Micon has accumulated rich design experience and processing technology in thin-walled injection moulds, creating unparalleled performance for thin-walled injection moulds.

At the same time, it reflects the best value of high speed injection molding, minimum injection point, high precision balance of heat flow channel and saving injection material.

Here is our website to have a look that we made many plastic moulds for our customers. www.mouldfactory.com

If any plastic mould project interested, please don’t hesitate to contact us by mail or phone.

Email: miconmould@gmail.com

Whatsapp and Wechat ID: +86 15306761345

Skype: miconmold